Industrial Robot Manufacturers: Revolutionizing the Manufacturing Industry

The manufacturing industry has undergone significant transformations over the decades, and one of the most remarkable advancements has been the integration of robotic technology. Robotic arms, with their precision and efficiency, have revolutionized various industrial processes, making them faster, more reliable, and cost-effective. In this article, we explore the world of industrial robot manufacturers and delve into the cutting-edge technology they employ to meet the growing demands of the market.

Introducing Industrial Robot Manufacturers

One of the leading Chinese robotic arm manufacturers, based in Haian city near Shanghai, is at the forefront of this technological revolution. With a strong focus on intelligent automation, this company has gained a reputation for producing high-quality robots that cater to diverse industries.

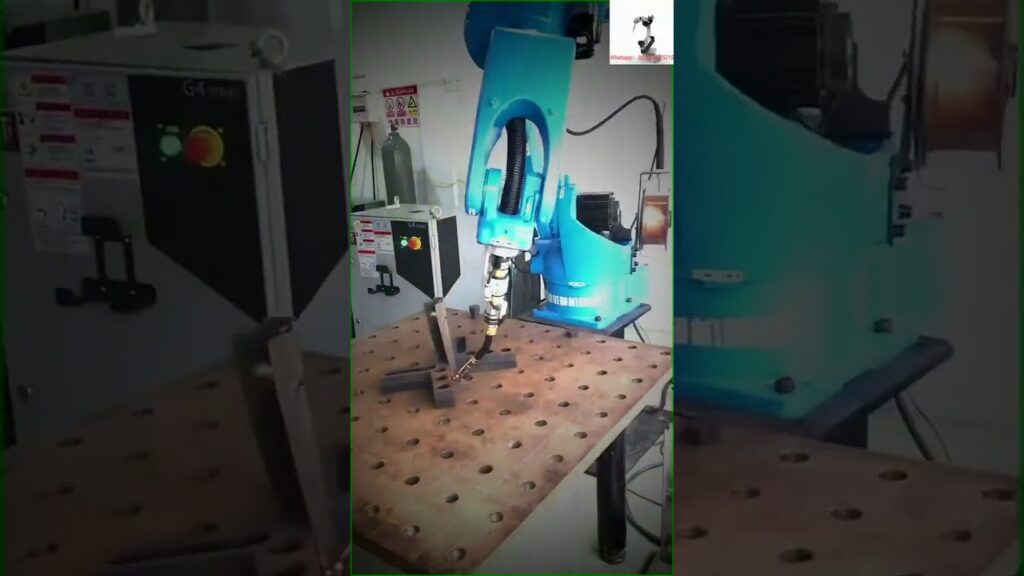

The 6 Axis Industrial Robotic Arm Price Collaborative Welding Robot Arm manufactured by our featured company, for instance, showcases their unmatched expertise. Designed to execute complex welding tasks with utmost precision, this robotic arm is equipped with advanced sensors and software, enabling it to adapt to different working conditions. Its collaborative nature ensures seamless interaction and coordination with human workers, fostering a more efficient and harmonious working environment.

The Significance of Industrial Robotic Arms

The advent of industrial robotic arms has paved the way for countless advancements in various sectors. These highly adaptable machines can be programmed to perform a wide range of tasks, from assembly and welding to material handling and packaging. By replacing manual labor, these robots not only boost productivity but also minimize human error, thereby improving the overall quality of manufactured products.

Additionally, industrial robotic arms offer immense flexibility and scalability. With the ability to work around the clock and perform repetitive tasks with precision, these robots facilitate increased production capacity and reduced costs. Moreover, these machines can be easily reprogrammed and reconfigured, allowing manufacturers to adapt to changing market demands swiftly.

Technology Driving the Transformation

The key technology driving the transformation in the manufacturing industry is artificial intelligence (AI). Industrial robot manufacturers have embraced AI to enhance the capabilities of their robotic arms. These intelligent machines can now analyze data in real-time, make judgments, and adjust their movements accordingly.

The integration of AI has also facilitated the development of collaborative robots, commonly known as cobots. These robots function alongside human workers, sharing the workspace and responsibilities, which increases efficiency while assuring worker safety. The collaborative welding robot arm, for example, can be manipulated through simple hand gestures, making it extremely user-friendly.

Furthermore, the Industrial Robot Manufacturers have implemented other cutting-edge technologies, such as computer vision, machine learning, and advanced sensors. Computer vision enables robots to recognize objects and interpret visual information. Machine learning equips these robots with the ability to learn and improve their performance over time. Advanced sensors allow the robots to detect and respond to their environment, ensuring seamless and efficient operations.

The Future of Industrial Robotics

As we move forward, the demand for industrial robots and their applications will continue to grow. Industrial robot manufacturers are tirelessly working towards further improving the capabilities of robotic arms, with the focus on enhancing connectivity, collaboration, and adaptability.

Connectivity plays a crucial role in the era of Industry 4.0, where automation, data exchange, and autonomous systems are integrated. By employing Internet of Things (IoT) connectivity, future industrial robots will be able to communicate and share information in real-time, thereby optimizing production processes.

Collaboration between humans and robots will become increasingly seamless, fostering a harmonious and efficient working environment. The Industrial Robot Manufacturers are investing significant efforts in developing robots that can understand and interpret human intentions, making interaction more intuitive and natural.

Moreover, adaptability will become a defining feature of future industrial robots. With an emphasis on modularity and interoperability, these robots will be able to quickly adapt to different tasks, ensuring maximum utilization throughout their lifecycle.

Conclusion

Industrial robot manufacturers are playing a pivotal role in the transformative journey of the manufacturing industry. With their advanced technology and innovative solutions, they are driving efficiency, enhancing productivity, and improving the overall quality of products. The 6 Axis Industrial Robotic Arm Price Collaborative Welding Robot Arm is just one example of the remarkable contributions these manufacturers are making.

As we look towards the future, the integration of AI, IoT connectivity, and advanced sensors will further revolutionize industrial robotics. The possibilities are endless, and as industrial robot manufacturers continue to push the boundaries of innovation, we can expect even greater advancements in the coming years. The manufacturing industry, with its reliance on automation and robotics, is on the cusp of a new era, where efficiency and precision reign supreme.

Industrial Robot

"Best Deals on Collaborative Welding Robots: Explore 6-Axis Industrial Robotic Arm Prices from Top Manufacturers"