Industrial Robots Applications: Enhancing Efficiency and Accuracy in Machine Tending Tasks

Introduction

In today’s fast-paced manufacturing industry, optimizing efficiency and accuracy have become paramount for businesses looking to stay ahead of the competition. Machine tending tasks, such as screwdriving, assembly, palletizing, and general machine operation, are crucial aspects that require precision and reliability. This is where industrial robots come into play, revolutionizing the way these tasks are handled. With the advent of the SWIFTI CRB 1300 – a high payload machine tending application – companies can now achieve new levels of productivity. Let us delve into the capabilities of industrial robots and how they are transforming various applications.

Enhancing Productivity with Industrial Robots

Industrial robots have been designed to automate repetitive tasks, freeing up human operators to focus on more complex and value-added activities. Whether it is screwdriving, assembly, or palletizing, these robots bring consistency and precision to the table. The SWIFTI CRB 1300, with its impressive payload capacity, is particularly suited for high-intensity applications, where heavy parts need to be handled with utmost care. This newfound efficiency translates to reduced cycle times, increased production output, and improved overall productivity.

Screwdriving: A Task Made Easy

Screwdriving is a common machine tending task that requires precision and accuracy. Traditional methods relied heavily on manual labor, which could be time-consuming and error-prone. However, industrial robots, equipped with precise torque control and advanced vision systems, have revolutionized this process. The SWIFTI CRB 1300, with its high payload capacity, can effortlessly handle heavy parts while screwdriving, ensuring consistent torque application and minimizing the risk of screw stripping or over-tightening. This not only boosts productivity but also guarantees the quality and reliability of the finished products.

Assembly: From Tedious to Streamlined

Assembly operations involve intricate coordination and precise alignment. Human operators often face challenges while handling multiple components simultaneously, leading to assembly errors and increased cycle times. By introducing industrial robots into the equation, companies can streamline the assembly process, thanks to their superior speed, accuracy, and repeatability. The SWIFTI CRB 1300, with its high payload capacity and advanced vision systems, can swiftly pick and place components with precision, ensuring flawless assembly every time. This not only cuts down on human errors but also reduces assembly time and improves overall efficiency.

Palletizing: From Heavy Lifting to Robot Assistance

Palletizing is a labor-intensive task that involves heavy lifting and stacking of products onto pallets. Human operators performing this task may face physical strain, fatigue, and the risk of injuries. Industrial robots equipped with high payload capacities, such as the SWIFTI CRB 1300, can effortlessly handle heavy products and precisely stack them onto pallets. These robots are not only more efficient but also create a safer working environment by removing the need for manual labor in lifting heavy objects. By automating palletizing tasks, companies can significantly reduce labor costs, increase throughput, and ensure consistent pallet quality.

Machine Tending: Redefining Precision and Reliability

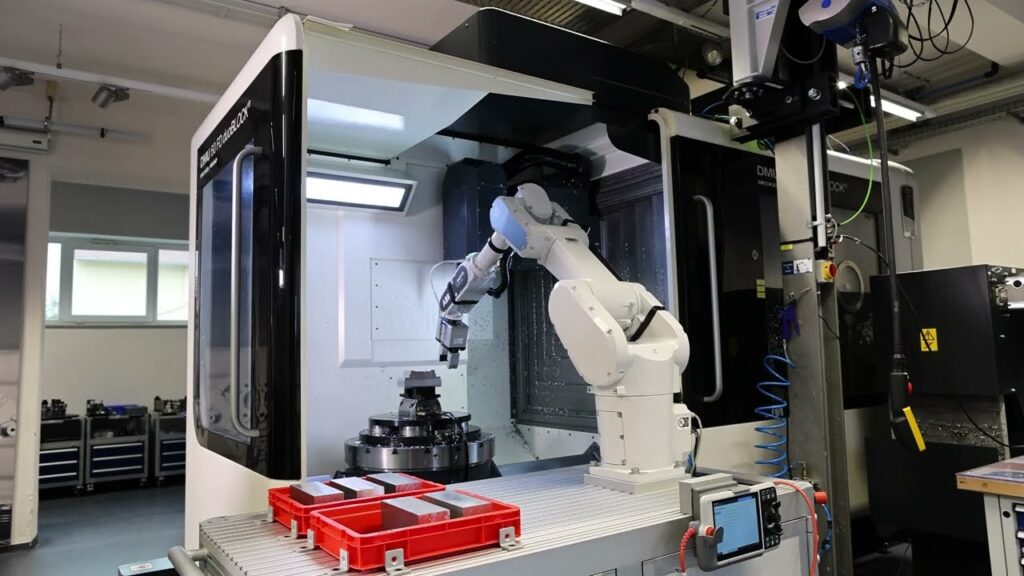

Machine tending, a crucial task in various industries, involves loading, unloading, and monitoring machines. Precision and reliability are essential for seamless machine operations and avoiding costly interruptions. Industrial robots, with their excellent repeatability and precision, have transformed machine tending tasks. The SWIFTI CRB 1300, with its high payload capacity and advanced control systems, can flawlessly handle heavy parts, reducing cycle times and ensuring uninterrupted machine operations. By implementing these robots, companies can enhance productivity, reduce downtime, and maintain consistent production output.

Conclusion

Industrial robots have revolutionized a wide range of machine tending tasks, including screwdriving, assembly, palletizing, and machine tending itself. The SWIFTI CRB 1300, with its high payload capacity and advanced features, has proven to be a game-changer in the manufacturing industry. By automating these tasks, companies can achieve levels of efficiency and accuracy that were once unimaginable. With reduced cycle times, increased production output, improved quality control, and enhanced worker safety, it is evident that the applications of industrial robots are transforming the manufacturing landscape. Embracing this technology is the key to staying competitive in today’s dynamic marketplace.

Industrial Robot

“Optimizing Efficiency: High-Payload Machine Tending with SWIFTI CRB 1300, Empowering Industrial Robots Applications”