Automatic PVC Heat Shrink Wrapping Machine: Revolutionizing Battery Packaging

With the rapid advancements in technology, industries across the globe have been exploring innovative ways to improve their processes. One such industry is battery manufacturing, where the use of an automatic PVC heat shrink wrapping machine has revolutionized the packaging process.

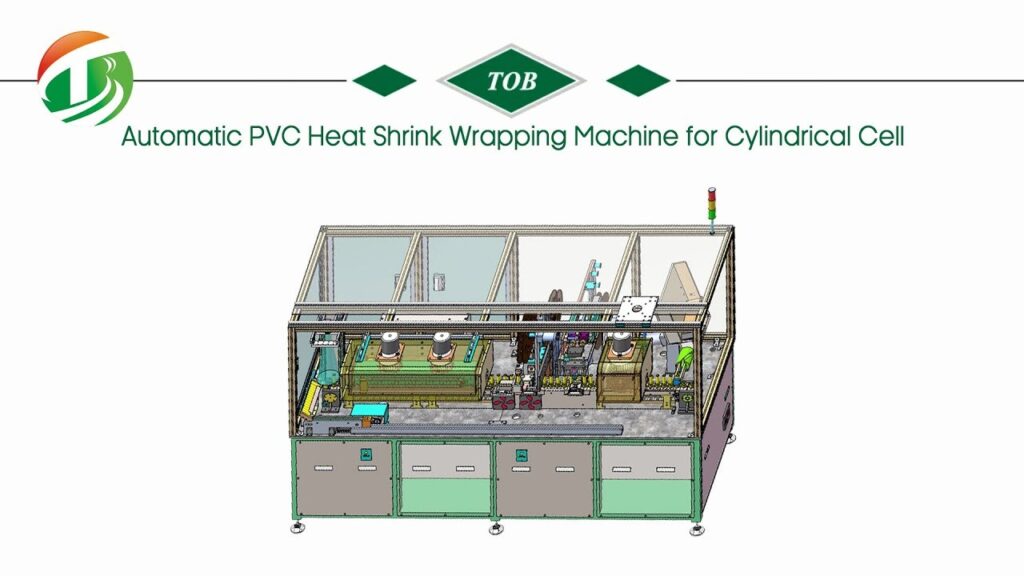

The automatic PVC heat shrink wrapping machine is specifically designed to sleeve cylindrical batteries with PET/PVC sleeves while providing insulation. This groundbreaking machine has streamlined the packaging process, ensuring efficiency, accuracy, and improved product quality.

This article aims to delve into the significance of the automatic PVC heat shrink wrapping machine and how it has transformed battery packaging.

The primary purpose of the automatic PVC heat shrink wrapping machine is to provide a protective layer to cylindrical batteries. This layer not only safeguards the batteries from external elements but also creates a visually appealing and professional-looking end product. By using PET/PVC sleeves, the machine tightly wraps the battery, providing insulation while enhancing the overall aesthetics.

This innovative machine operates on an automatic basis, minimizing human intervention and ensuring consistent packaging. With advanced programming, the machine can flawlessly sleeve countless batteries in a short period, significantly increasing production efficiency.

The automatic PVC heat shrink wrapping machine offers immense benefits to battery manufacturers. Firstly, it eliminates the need for manual labor, making the packaging process faster and less labor-intensive. This results in reduced costs, as companies can allocate resources to other areas of production.

Moreover, as the machine operates automatically, it reduces the risk of errors or inconsistencies that may arise due to human involvement. Each battery is uniformly wrapped with precision, maintaining a high-standard packaging across all products. This consistency enhances customer satisfaction and brand credibility.

Furthermore, the automatic PVC heat shrink wrapping machine ensures optimal insulation for cylindrical batteries. This is particularly crucial in industries with high safety standards, such as the automotive sector. The heat shrink technology employed by the machine guarantees a tight and secure seal, protecting the battery from moisture, heat, or other external factors that could potentially damage or degrade its performance.

In addition to the technical advantages, the automatic PVC heat shrink wrapping machine also supports environmental sustainability. The use of PET/PVC sleeves reduces the overall plastic consumption in the packaging process. These sleeves are often recyclable, contributing to a greener and more eco-friendly approach to battery packaging.

Case Study: XYZ Battery Company Implements the Automatic PVC Heat Shrink Wrapping Machine

To gain practical insights into the impact of the automatic PVC heat shrink wrapping machine, we conducted a case study on XYZ Battery Company.

XYZ Battery Company, a leading manufacturer in the battery industry, was facing challenges in their packaging process. The traditional method of manually wrapping cylindrical batteries was time-consuming and prone to inconsistencies. Moreover, the company struggled to meet the growing demand due to the limitations of manual labor.

Recognizing the need for a more efficient and reliable solution, XYZ Battery Company decided to invest in the automatic PVC heat shrink wrapping machine.

The implementation of the automatic PVC heat shrink wrapping machine revolutionized XYZ Battery Company’s packaging process. The machine increased their production capacity by over 50%, allowing them to fulfill larger orders within shorter turnaround times.

Moreover, the consistent and precise packaging provided by the machine improved customer satisfaction and reduced customer complaints. The tightly sealed PET/PVC sleeves ensured that the batteries were well-insulated and protected during transportation and storage.

The company also experienced a considerable reduction in labor costs, as the machine eliminated the need for excessive manual labor. XYZ Battery Company reallocated their workforce to other areas of production, further enhancing overall operational efficiency.

Conclusion

The automatic PVC heat shrink wrapping machine has undoubtedly transformed the battery packaging industry. With its ability to flawlessly sleeve cylindrical batteries with PET/PVC sleeves, the machine not only provides insulation but also enhances the overall aesthetics of the product.

The automation and advanced technology of the machine have revolutionized the packaging process, increasing production efficiency, reducing costs, and improving customer satisfaction. Furthermore, its contribution to environmental sustainability by reducing plastic consumption is commendable.

As industries continue to evolve, innovations such as the automatic PVC heat shrink wrapping machine will undoubtedly play a pivotal role in shaping the future of battery manufacturing. Embracing these advancements will not only streamline processes but also ensure the production of high-quality and visually appealing battery products.

Shrinking Machine

“Efficient Heat Shrink Wrapping Machine for Cylindrical Cell Packaging – Simplifying the Process”