Industrial Robots Applications: A Comprehensive Overview

Advancements in technology have revolutionized numerous industries worldwide, and one such groundbreaking innovation is the industrial robot. These intelligent machines have reshaped the manufacturing landscape, streamlining production processes, enhancing efficiency, and enabling unparalleled precision. In this article, we will delve into the vast range of industrial robot applications and explore their transformative impact on various industries.

Overview of Industrial Robots

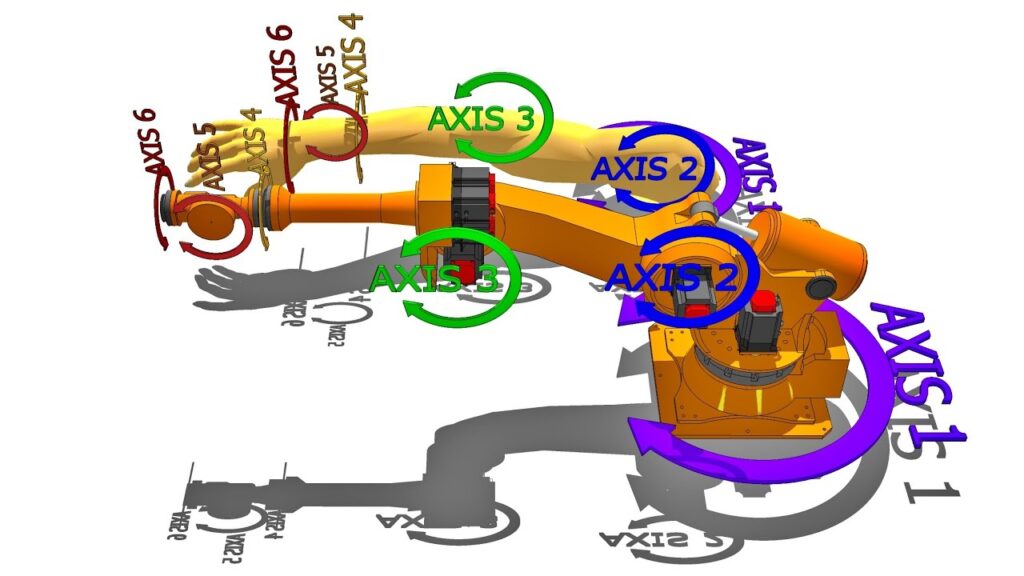

Industrial robots, also known as robotic arms, are programmable machines designed to perform repetitive tasks with a high degree of accuracy and speed. These machines are equipped with sensors, actuators, and sophisticated software, enabling them to function autonomously. Industrial robots have become an integral part of modern manufacturing, collaborating seamlessly with human workers on assembly lines and enhancing overall productivity.

The applications of industrial robots are diverse and far-reaching, catering to an array of industries including automotive, electronics, pharmaceuticals, and food processing. Let us explore some of the compelling applications that have revolutionized these sectors and set new standards of efficiency and precision.

Automotive Industry and Beyond

The automotive industry has been an early adopter of industrial robots on a large scale, recognizing their ability to automate tasks such as welding, painting, and assembly with unparalleled precision. These robots can perform these tasks relentlessly, ensuring consistency and reducing human error. As a result, production cycles have significantly shortened, allowing manufacturers to meet the growing demand for vehicles more efficiently.

Industrial robots have also proven their worth in the electronics industry, particularly in the assembly of intricate electronic components. Soldering, testing, and packaging processes in electronics manufacturing are now predominantly automated, reducing the risk of defects and optimizing production throughput. The advanced capabilities of industrial robots enable manufacturers to swiftly adapt to changes in product specifications, ensuring rapid production cycles in the fast-paced electronics industry.

Pharmaceutical and Healthcare Advancements

In the pharmaceutical industry, precision and sterile environments are critical factors in manufacturing processes. Industrial robots have emerged as the perfect solution, minimizing contamination risks and ensuring accuracy in dosage calculation and packaging. Furthermore, these robots can handle hazardous substances, safeguarding the health and safety of human workers. The seamless integration of industrial robots in pharmaceutical manufacturing has led to increased productivity, reduced errors, and enhanced overall quality control.

Industrial robots have also found applications in the healthcare sector. Surgical robots, for instance, have transformed the field of minimally invasive surgery, offering unparalleled precision and control to surgeons. These robots assist in complex procedures, resulting in reduced trauma, faster recovery times, and improved patient outcomes. Moreover, robotic exoskeletons and prosthetics are revolutionizing physical rehabilitation by providing support and mobility to individuals with disabilities.

Food Processing and Packaging

The food processing industry has witnessed significant advancements with the adoption of industrial robots. From sorting and handling raw ingredients to packaging the final product, robots have streamlined various stages of the food production chain. These robots excel in tasks requiring delicate handling, such as egg processing and sorting fruits based on size and ripeness. By automating these processes, manufacturers ensure consistent quality, reduce waste, and optimize productivity.

Applications of industrial robots are not limited to manufacturing, as they have permeated various other sectors. For instance, in warehouses, robots facilitate efficient material handling, optimizing inventory management and order fulfillment. In hazardous environments, such as nuclear power plants, robots can be deployed for inspection and maintenance tasks that would otherwise pose risks to human operators.

Conclusion

The advent of industrial robots has ushered in a new era of automation and efficiency across diverse industries. Their transformative impact is evident in automotive manufacturing, electronics assembly, pharmaceutical production, healthcare advancements, food processing, and many more sectors. As technology continues to evolve, industrial robots are poised to become even more versatile and sophisticated, further shaping the future of manufacturing. Embracing the potential of these intelligent machines will undoubtedly result in increased productivity, reduced costs, and improved quality across industries worldwide.

Industrial Robot

"Revolutionizing Manufacturing: Exploring Applications and Capabilities of Industrial Robots"