How Car Factory Robots Are Revolutionizing Automotive Manufacturing and Assembly

The automotive industry is witnessing profound changes as technology continues to advance at an unprecedented pace. One of the most significant advancements in recent years is the integration of robots into car factories, where they play a vital role in manufacturing and assembly processes. In this article, we will explore how car factory robots are revolutionizing automotive manufacturing and assembly, and delve into the world of industrial robot manufacturers.

Car production has always been a labor-intensive process. However, thanks to innovations in robotics, car manufacturers are now able to automate various tasks, improving efficiency and reducing costs. Industrial robot manufacturers, such as ABB, FANUC, and KUKA, have played a pivotal role in developing and supplying highly sophisticated robots for the automotive industry.

Industrial robots are designed to perform repetitive and strenuous tasks with precision and speed. They are capable of carrying out a wide range of activities, such as welding, painting, and assembly, which were previously done manually. These robots are equipped with advanced sensors and sophisticated programming that enable them to execute complex tasks with high levels of accuracy.

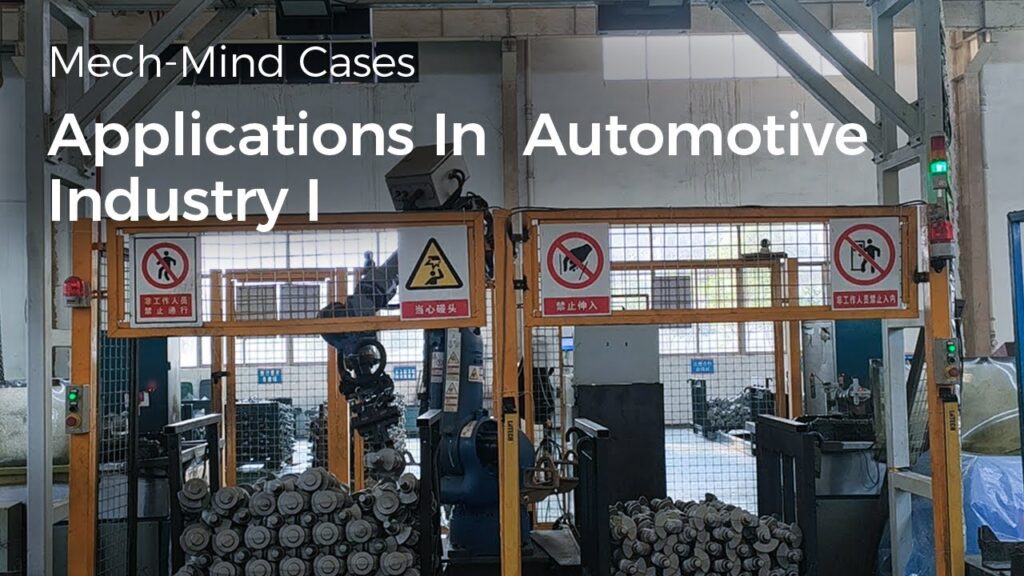

In the first part of the "How Car Factory Robots Realize Automotive Manufacturing and Assembly" video series, we gained valuable insights into the inner workings of car factory robots. The video showcased the different types of robots used in car manufacturing, such as articulated robots, Cartesian robots, and SCARA robots. Each of these robots has its own unique characteristics and is deployed for specific tasks on the production line.

Articulated robots, also known as six-axis robots, are the most commonly used robots in car manufacturing. They have a high degree of freedom, allowing them to move and operate in multiple directions. These robots are often utilized for welding and assembly tasks, as their flexible arms can reach around obstacles and work in tight spaces.

Cartesian robots, on the other hand, operate on a three-axis system and are ideal for tasks that require linear movement, such as pick and place operations. These robots are typically used for material handling and transferring components from one station to another on the assembly line.

SCARA robots, short for Selective Compliance Assembly Robot Arm, are known for their speed and precision. They are often used for assembly tasks that require a high degree of accuracy, such as inserting screws or connectors. These robots have a cylindrical appearance and can quickly navigate between different workstations with ease.

The integration of these robots into car factories has brought forth a myriad of benefits. Firstly, robots can perform tasks with consistent precision, reducing the margin of error and improving the overall quality of the cars being produced. Additionally, robots are not subject to fatigue or physical limitations, allowing them to work tirelessly without breaks.

Moreover, by employing robots in car manufacturing, companies can significantly increase their production capacity. Robots are capable of working at unparalleled speeds, ensuring that cars are manufactured at a much faster rate than through manual labor. This accelerated production can help satisfy the growing demand for automobiles in a timely manner.

Furthermore, car factory robots contribute to workplace safety. They can handle hazardous tasks, such as welding or working with toxic chemicals, which would otherwise pose significant risks to human workers. By removing humans from potentially dangerous environments, the likelihood of accidents and injuries is substantially reduced.

Despite the undeniable advantages offered by car factory robots, there are some concerns surrounding their widespread adoption. Critics argue that the integration of robots may lead to job losses as human workers are replaced by automated systems. While it is true that some jobs may become obsolete, the emergence of new roles focused on maintaining and operating these robots creates a need for a skilled workforce.

In conclusion, the automotive industry is rapidly evolving, with car factory robots playing a crucial role in transforming manufacturing and assembly processes. Industrial robot manufacturers are at the forefront of this revolution, providing sophisticated robots that are capable of executing complex tasks with precision and speed. As technology continues to advance, we can expect car factory robots to become even more intelligent and efficient, revolutionizing the way cars are built. The automotive industry has truly entered a new era, thanks to the remarkable capabilities of industrial robots.

Industrial Robot

"The Incredible World of Car Factory Robots: Unveiling the Automotive Manufacturing and Assembly Process (Part I) & Unveiling Industrial Robot Manufacturers"