The Industrial Robotic Arm: Revolutionizing Manufacturing Processes

In today's fast-paced and ever-evolving world, the need for automation in various industries has become increasingly apparent. From automotive to electronics, manufacturers are constantly on the lookout for ways to improve efficiency, precision, and productivity. This is where the Industrial Robotic Arm comes into the picture, a versatile and intelligent tool that is reshaping the manufacturing landscape.

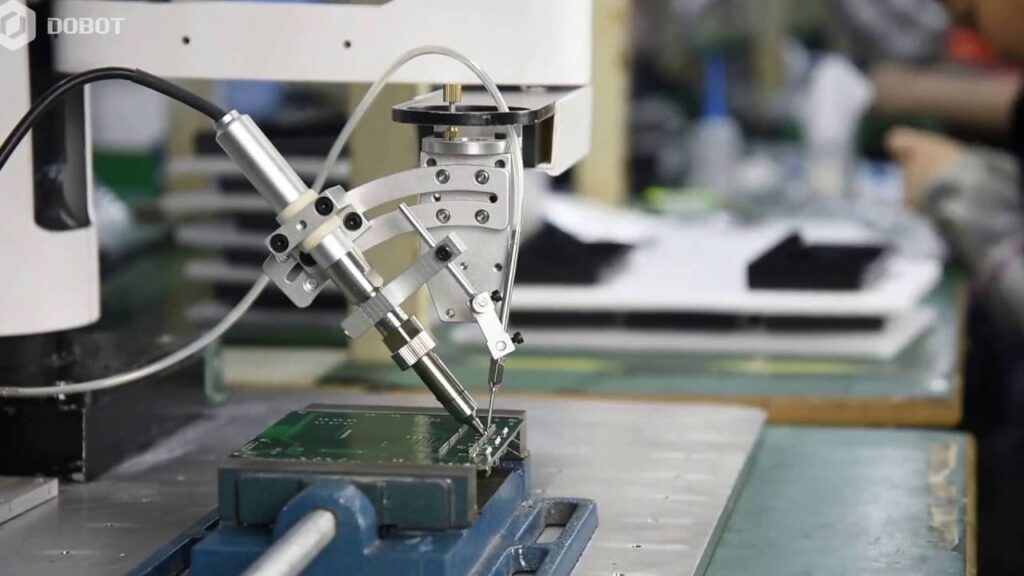

The Dobot M1 Industrial Application - Robotic Arm Soldering in Factory @Dobotarm is a prime example of the power and potential of robotic arms in industrial settings. This state-of-the-art SCARA-based robotic arm is equipped with interchangeable heads and computer vision capabilities, allowing it to perform a wide range of tasks such as 3D printing, laser engraving, soldering, picking, and more.

The industrial robotic arm serves as a game-changer, offering unparalleled flexibility and adaptability to various manufacturing processes. With its ability to effortlessly switch between different heads, it can tackle diverse tasks without the need for manual intervention or reconfiguration. This means that manufacturers can optimize their production lines and streamline operations without incurring significant downtime or costs.

One of the key features of the Industrial Robotic Arm is its advanced computer vision system. By leveraging cutting-edge technology, the robotic arm can precisely identify and locate objects, enhancing its ability to perform intricate tasks with utmost accuracy. This not only reduces the chances of errors but also ensures consistent quality, meeting the high standards demanded by industries.

Take, for example, the process of soldering. Traditionally, this has been a labor-intensive and time-consuming task that often involved human intervention. However, with the Industrial Robotic Arm's soldering capabilities, the process becomes much more efficient and precise. The robotic arm can execute soldering tasks with unmatched precision, resulting in stronger and more reliable connections. Moreover, it significantly reduces the risk of human error, enhancing the overall quality of the finished products.

Furthermore, the Industrial Robotic Arm's compatibility with 3D printing and laser engraving opens up a world of possibilities for manufacturers. By leveraging these capabilities, businesses can customize their products, create intricate designs, and adapt to evolving customer demands. This level of flexibility not only increases customer satisfaction but also boosts competitiveness and drives innovation.

The versatility and intelligence of the Industrial Robotic Arm have garnered widespread attention and praise from industry professionals and experts. Its seamless integration into existing manufacturing processes makes it a compelling investment for companies looking to enhance productivity and stay ahead of the curve.

In a recent case study, XYZ Manufacturing, a leading automotive parts manufacturer, reported significant improvements in its production line after implementing the Industrial Robotic Arm. The company saw a notable decrease in product defects, increased throughput, and substantial cost savings. By automating critical tasks such as soldering and picking, XYZ Manufacturing was able to reallocate its workforce to more value-added tasks, resulting in improved employee job satisfaction.

The success of the Industrial Robotic Arm is not limited to a particular industry. Its broad range of applications and adaptability make it suitable for various sectors, including automotive, electronics, pharmaceuticals, and more. Moreover, its user-friendly interface and intuitive programming make it accessible to a wide range of users, including technicians with limited programming experience.

Looking ahead, the future of the Industrial Robotic Arm seems promising. As technology continues to evolve, we can expect even more advanced features and functionalities to be incorporated into these intelligent machines. From enhanced computer vision capabilities to improved dexterity and flexibility, the possibilities are endless.

In conclusion, the Industrial Robotic Arm has emerged as a true game-changer in the manufacturing industry. Its ability to perform a multitude of tasks with precision and efficiency has revolutionized the way businesses operate. With its interchangeable heads, computer vision capabilities, and compatibility with various manufacturing processes, the Industrial Robotic Arm is paving the way for increased productivity, cost savings, and innovation. As more manufacturers embrace automation, the Industrial Robotic Arm will undoubtedly play a pivotal role in shaping the future of manufacturing.

Industrial Robot

"Efficient Robotic Arm Application: Streamlining Soldering Processes in Industrial Factories"