Industrial Robots in Manufacturing: Revolutionizing the Production Line

From the earliest days of the Industrial Revolution, the pursuit of automation has driven manufacturing industries to push the boundaries of efficiency and productivity. While the utilization of machines and assembly lines has become commonplace, a new player has emerged on the scene: industrial robots. These highly sophisticated machines are transforming the face of manufacturing, offering unparalleled precision, speed, and versatility. In this article, we will delve into the world of industrial robots and explore their impact on the manufacturing sector.

Industrial robots have come a long way since their inception. Initially, they were primarily used for mundane and repetitive tasks, such as welding and painting. However, with advancements in technology, these robots have evolved into highly intelligent and adaptable machines capable of handling a wide range of complex manufacturing processes.

One of the primary advantages of industrial robots is their ability to perform tasks with meticulous precision. Unlike human workers who may tire or make errors, robots maintain consistent accuracy, resulting in improved product quality and reduced waste. As a technical engineer who has witnessed firsthand the benefits of industrial robots, I can attest to their unrivaled efficiency and reliability on the production line.

With the advent of artificial intelligence and machine learning, robots are no longer just mechanized arms mindlessly executing instructions. They are now equipped with advanced sensors, computer vision, and complex algorithms that enable them to adapt in real-time to changing conditions. This makes them perfect for dynamic manufacturing environments where adaptability is key.

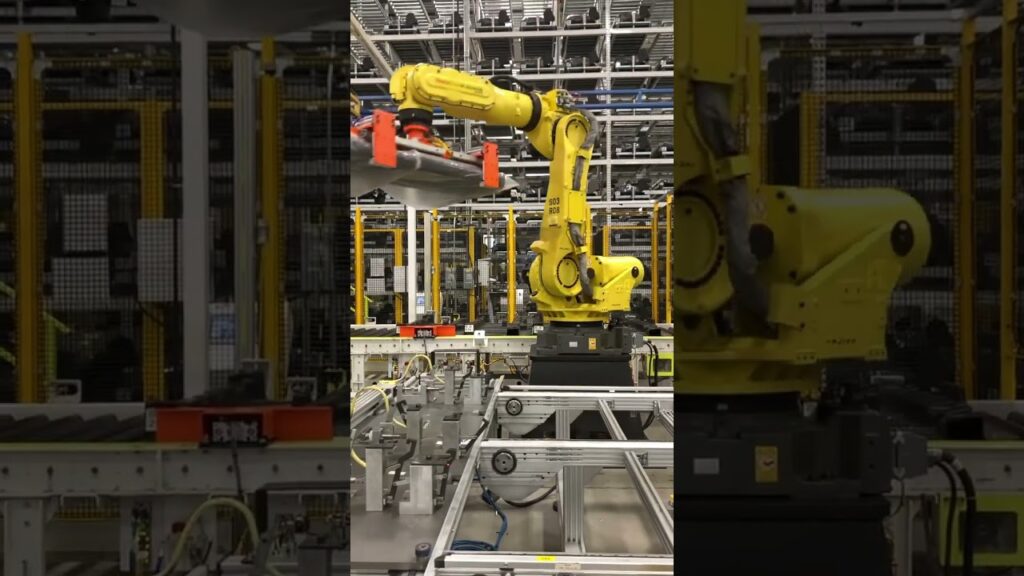

A fascinating use case of industrial robots in manufacturing is demonstrated in the YouTube video "Massive Industrial Robot Moves Car Parts." This video showcases the immense power and agility of these machines as they effortlessly handle large automotive components with precision and ease. The ability to maneuver heavy and unwieldy objects with such finesse is a testament to the effectiveness of industrial robots in streamlining production processes.

Moreover, industrial robots are not simply limited to performing physical tasks. They can also play a vital role in data collection and analysis, enabling manufacturers to make informed decisions and optimize their operations. By harnessing the power of automation and big data, companies can identify patterns, detect anomalies, and predict maintenance requirements, ultimately leading to enhanced productivity and cost savings.

As the industrial robotics market continues to grow, it is worth considering the potential implications for the workforce. While some may fear job displacement, the reality is that industrial robots can coexist with human workers, augmenting their capabilities rather than replacing them. By automating repetitive and physically demanding tasks, robots free up human workers to focus on more strategic and creative aspects of the manufacturing process.

However, it is crucial for companies to prioritize retraining and upskilling their workforce to adapt to this paradigm shift. Technical expertise in operating and maintaining industrial robots will be in high demand, and companies must invest in training programs to equip their employees with the necessary skills for the future.

In conclusion, industrial robots are revolutionizing the manufacturing industry, offering unparalleled precision, adaptability, and efficiency. With advancements in technology, these machines are no longer confined to monotonous tasks but can handle complex processes with ease. As a technical engineer, I am excited to witness the transformative power of industrial robots on the production line and look forward to a future where human workers and robots collaborate seamlessly to drive innovation and productivity in manufacturing.

Industrial Robot

"Giant Industrial Robot Revolutionizes Automotive Assembly Line: Efficiently Manipulating Car Parts"