Robots have come a long way in transforming the industrial landscape. From performing repetitive tasks to handling intricate operations, industrial robots have revolutionized the manufacturing industry. In this article, we will explore the different types of industrial robots and how they have changed the face of production.

Nowadays, it is not uncommon to find robots working side by side with humans on the production line. These advanced machines have the ability to perform tasks with precision, speed, and efficiency, which ultimately leads to increased productivity and reduced costs.

One of the most common types of industrial robots is the Cartesian robot. This type of robot operates on a three-axis system that allows for precise movements along the X, Y, and Z axes. Cartesian robots are often used in applications that require repetitive movements, such as picking and placing components on an assembly line. With their high accuracy and repeatability, these robots have become an integral part of various manufacturing processes.

Another type of industrial robot is the SCARA robot, which stands for Selective Compliance Assembly Robot Arm. SCARA robots are typically used for tasks that require both horizontal and vertical movements, such as assembly or picking and placing objects. These robots are known for their speed and precision, making them ideal for applications where a high degree of accuracy is required.

Next, we have the Delta robot, which is often seen in industries where fast and precise movements are crucial. Delta robots are commonly used in applications such as packaging, sorting, or pick and place operations. With their unique design and lightweight structure, these robots can perform tasks at astonishing speeds, significantly improving production rates.

Collaborative robots, or cobots, are another type of industrial robot that have gained popularity in recent years. These robots are designed to work alongside humans, assisting them in various tasks. Unlike traditional robots that require safety barriers to separate them from humans, cobots are equipped with advanced sensors and safety features that allow them to work in close proximity to their human counterparts. Collaborative robots are highly versatile and can be easily programmed to perform a wide range of tasks, making them a valuable asset in any manufacturing environment.

Industrial robots are not limited to performing tasks in controlled environments. With advancements in technology, autonomous robots have emerged as a game-changer in industries such as agriculture and logistics. These robots are equipped with sensors and advanced algorithms that allow them to navigate through complex environments and perform tasks independently. Autonomous robots have the potential to revolutionize various industries by increasing efficiency and reducing the need for human intervention in labor-intensive tasks.

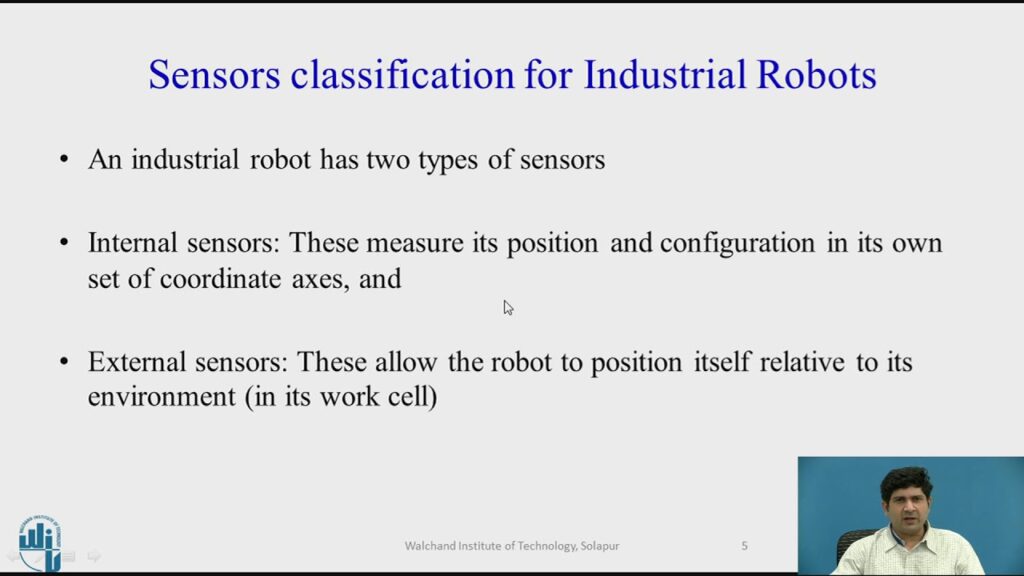

Industrial robot sensors play a crucial role in ensuring the smooth and safe operation of these complex machines. These sensors can detect objects, measure distances, and monitor various parameters to ensure that the robot performs its tasks accurately and efficiently. Some common types of industrial robot sensors include proximity sensors, vision sensors, force sensors, and temperature sensors. These sensors provide valuable feedback to the robot's control system, allowing it to adjust its movements and interact with its surroundings effectively.

In conclusion, industrial robots have transformed the manufacturing industry, enabling higher productivity, efficiency, and accuracy in various processes. The different types of robots, such as Cartesian robots, SCARA robots, Delta robots, collaborative robots, and autonomous robots, cater to different applications and requirements. With the help of advanced sensors, industrial robots can navigate complex environments and interact with objects and humans safely. As technology continues to advance, industrial robots will only become more sophisticated, revolutionizing the way we produce goods and enhancing the overall efficiency of manufacturing processes.

Industrial Robot

"The Ultimate Guide to Industrial Robot Sensors and Different Types of Industry Robots"