Automated Packaging Systems: Revolutionizing the Packaging Industry

In today’s fast-paced world, where efficiency is key, the need for automated systems has become increasingly apparent. One area where automation has truly taken off is in the packaging industry. Gone are the days of manually packing products into boxes or bags; instead, companies are turning to Automated Packaging Systems to streamline their operations and improve productivity. In this article, we will explore the various benefits of these systems and how they are changing the game for businesses worldwide.

Automated Packaging Systems, as the name suggests, are computer-controlled systems that automate the packaging process. By reducing the need for manual labor, these systems not only increase efficiency but also minimize errors and improve overall product quality. One such system that has gained significant attention is the Automated Packaging Systems – Maximizer Indexing Infeed Conveyor.

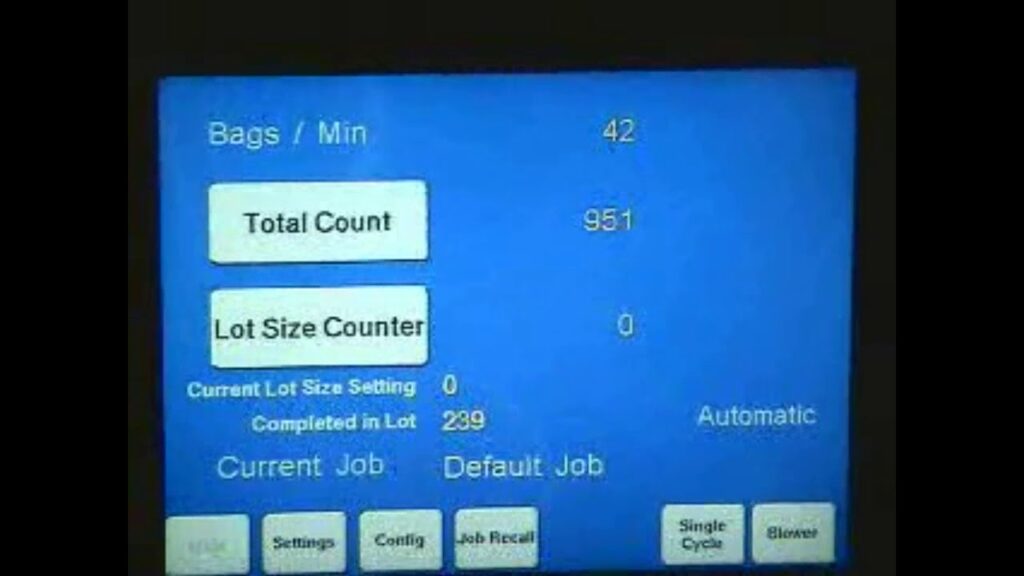

The Maximizer Indexing Infeed Conveyor is a state-of-the-art system that offers unparalleled precision and reliability in the packaging industry. It integrates seamlessly with other automated packaging machines, allowing for a smooth and continuous workflow. With a compact design and high-speed capabilities, this system is perfect for businesses with high-volume packaging needs.

One of the key advantages of Automated Packaging Systems is their ability to increase productivity. By automating the packaging process, companies can significantly reduce the time it takes to package products. This not only enables them to meet tight deadlines but also allows for faster order fulfillment, leading to increased customer satisfaction.

Moreover, these systems eliminate human error, ensuring consistent packaging quality. With manual packaging, there is always a chance of errors, such as incorrect product quantities or improper sealing. However, with Automated Packaging Systems, each package is precisely measured and sealed, reducing the possibility of mistakes and ensuring that customers receive their products in perfect condition.

The Maximizer Indexing Infeed Conveyor takes productivity to the next level by offering advanced features such as adjustable indexing speed and customizable package sizes. This flexibility allows businesses to adapt to changing market demands and streamline their operations further.

Another significant advantage of Automated Packaging Systems is their cost-effectiveness. While the initial investment may seem substantial, the long-term benefits outweigh the costs. Automated systems require minimal maintenance and have a low error rate, resulting in fewer product losses. Additionally, by eliminating the need for manual labor, businesses can reduce their workforce and allocate resources to other essential areas of their operations.

Furthermore, these systems are environmentally friendly. With a focus on sustainability, many companies are looking for ways to reduce their carbon footprint. Automated Packaging Systems help in achieving this by optimizing material usage and minimizing waste. By calculating the exact amount of packaging material required for each product, these systems reduce excess packaging and contribute to a greener future.

The Maximizer Indexing Infeed Conveyor excels in this area as well. With its precise measurements, businesses can avoid the unnecessary use of packaging materials, ultimately reducing waste and promoting eco-conscious practices.

In conclusion, Automated Packaging Systems are transforming the packaging industry, revolutionizing the way products are packaged and delivered. Through increased productivity, improved product quality, cost-effectiveness, and environmental sustainability, these systems offer a plethora of benefits for businesses of all sizes.

The Maximizer Indexing Infeed Conveyor, with its cutting-edge features and seamless integration capabilities, is at the forefront of this automation revolution. As businesses strive to stay ahead in a competitive market, investing in automated packaging systems like this is quickly becoming a necessity rather than a luxury.

As we move into the future, it is clear that automation will continue to be a driving force in the packaging industry. The advantages offered by Automated Packaging Systems cannot be ignored, and businesses that choose to embrace this technology will undoubtedly reap the rewards. Whether it be increased efficiency, improved product quality, or cost savings, the benefits are endless. So, why wait? Explore the world of Automated Packaging Systems today and take your packaging operations to new heights!

Automatic Packing Line

“Efficient Material Handling Solution: Discover the Maximizer Indexing Infeed Conveyor by APS”