Automated Filament Winding Lines Revolutionize Composite LPG Tank Production

The demand for composite LPG cylinders is on the rise, and advancements in technology are meeting this demand head-on. With the introduction of automated filament winding lines, the process of manufacturing these tanks has become more efficient and cost-effective. In this article, we will explore the groundbreaking development of an automatic handling machine that has transformed the production of composite LPG tanks.

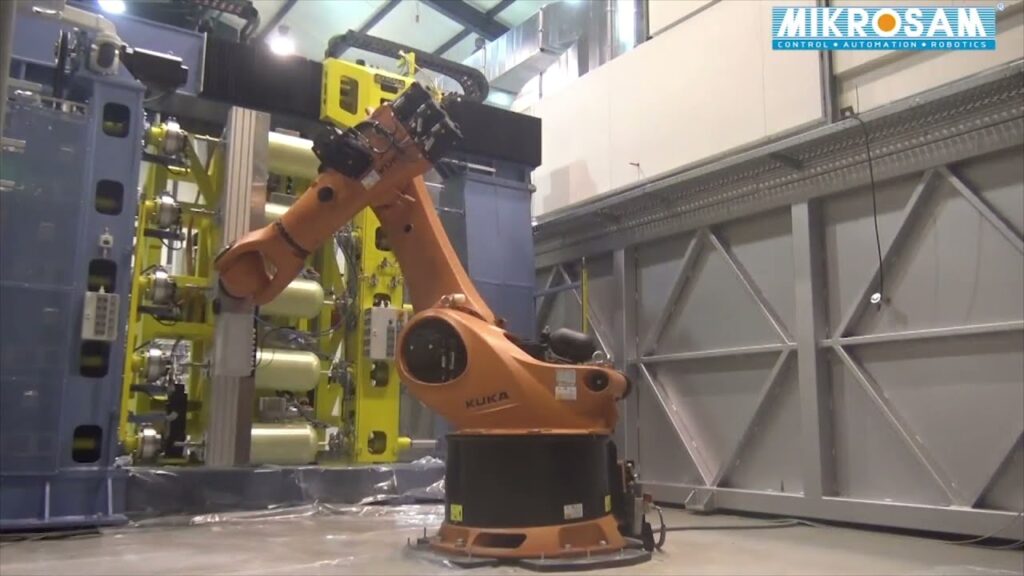

Historically, the production of composite LPG tanks has been a labor-intensive process. However, with the advent of the Mikrosam Automated Line for Composite LPG Tanks: Filament Winding, Handling & Curing, the industry has witnessed a significant shift towards automation. This innovative solution brings numerous benefits, such as improved productivity, enhanced quality control, and reduced human error.

The Automatic Handling Machine, a key component of this automated system, has revolutionized the entire manufacturing process. This machine handles the LPG tanks with precision and accuracy, ensuring consistent results every time. By eliminating manual intervention, the risk of human error is minimized, leading to a higher standard of quality.

One of the standout features of the Automatic Handling Machine is its ability to efficiently wind and cure the composite filaments. This is achieved through advanced robotics and software, which work in conjunction to create a seamless and error-free process. The machine's filament winding capabilities ensure optimal composite reinforcement, resulting in tanks that are lightweight yet incredibly strong.

The Mikrosam Automated Line has also streamlined the curing process of the composite LPG tanks. With precise temperature control and monitoring, the tanks receive the ideal treatment to ensure maximum strength and durability. This meticulous curing process significantly improves the overall quality and reliability of the tanks.

The advantages of implementing an automated filament winding line for composite LPG tanks are far-reaching. Increased efficiency leads to a higher production rate, allowing manufacturers to meet the growing demand in the market. Moreover, the reduced labor requirements translate into cost savings for companies, making the production process more economically viable.

From the customer's perspective, the transition to automated manufacturing brings several benefits. Composite LPG tanks manufactured using the Mikrosam Automated Line exhibit superior quality and reliability compared to traditional methods. The precise control and monitoring of the process guarantee tanks that are not only safe but also long-lasting.

Furthermore, automating the production of composite LPG tanks contributes to sustainability efforts. The reduction in material waste and improved energy efficiency makes this method environmentally friendly. As the world prioritizes sustainable solutions, the composite LPG tank industry is taking a step in the right direction.

The use of an Automatic Handling Machine in conjunction with a filament winding line is a game-changer for the production of composite LPG tanks. The technical engineering behind this innovation has transformed the industry, offering an efficient, cost-effective, and environmentally friendly solution.

Looking ahead, it is evident that automation will continue to play a crucial role in the manufacturing sector. As technology continues to advance, it is foreseeable that more industries will adopt automated systems to meet increasing demands and ensure consistent quality.

In conclusion, the introduction of automated filament winding lines for composite LPG tanks is revolutionizing the industry. The implementation of the Mikrosam Automated Line, particularly the Automatic Handling Machine, has brought about improved efficiency, enhanced quality control, and increased sustainability. As the demand for composite LPG tanks continues to rise, manufacturers who embrace automation stand to gain a competitive edge in the market.

Handling Machine

"Revolutionizing Composite LPG Tank Production: Streamlined Filament Winding, Automated Handling & Curing"