Semi-Automatic Bagging Machines: Revolutionizing Industrial Packaging

In today’s fast-paced and competitive industrial landscape, efficiency and productivity play a vital role in determining a company’s success. With the constant need to package products quickly and accurately, businesses are turning to innovative solutions to enhance their packaging processes. One such solution that has gained popularity is the semi-automatic bagging machine.

The semi-automatic bagging machine has revolutionized the way industries package their goods. With its advanced features and customizable options, it offers a range of benefits that greatly improve the overall packaging process. Whether you are in the food, pharmaceutical, or automotive industry, these machines can be tailored to meet your specific requirements.

Gone are the days of manually packaging products, which not only consumes valuable time but also leaves room for human error. The semi-automatic bagging machine eliminates these concerns by providing a reliable and efficient automated packaging solution. It streamlines the packaging process, reducing the risk of errors and increasing production output.

What sets the semi-automatic bagging machine apart from its counterparts is its versatility. It can handle a wide range of products, from small items like screws and bolts to larger objects like automotive parts. The machine’s adaptability makes it a viable option for industries with varying packaging needs.

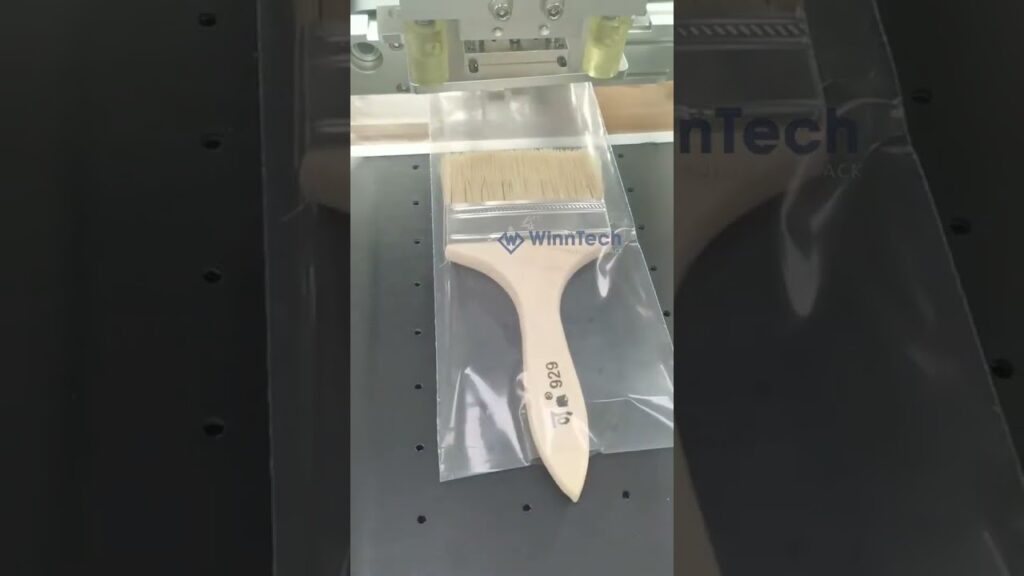

One industry that has greatly benefited from the implementation of semi-automatic bagging machines is the paintbrush manufacturing sector. Previously, packaging paintbrushes was a tedious and time-consuming task. The brushes had to be manually placed in bags, sealed, and labeled, which consumed a significant amount of labor hours. However, with the introduction of semi-automatic bagging machines, this arduous process has been transformed.

By integrating a customized semi-automatic bagging machine into their production line, paintbrush manufacturers have experienced a significant boost in productivity. These machines are designed to handle the delicate nature of paintbrushes, ensuring they are properly protected and packaged. The automated process not only reduces the chances of damage but also optimizes the packaging time, enabling manufacturers to meet the growing demand for their products.

The benefits of semi-automatic bagging machines extend beyond increased productivity. They also enhance product presentation and branding. These machines can be programmed to incorporate specific branding elements, including logos, product descriptions, and promotional messages. This helps businesses to create a cohesive brand identity, which is crucial in today’s highly competitive market.

Additionally, the semi-automatic bagging machine is equipped with advanced technology, ensuring accuracy and consistency in packaging. It can measure and dispense precise amounts of product, reducing wastage and minimizing costs. This level of precision is particularly essential in industries where every ounce of material counts, such as pharmaceuticals and chemicals.

The semi-automatic bagging machine also offers ease of use and maintenance. Its user-friendly interface allows operators to quickly adjust settings, change packaging materials, and troubleshoot any issues that may arise. Furthermore, regular maintenance and servicing of these machines are straightforward, minimizing downtime and maximizing operational efficiency.

As the demand for efficiency in industrial packaging continues to grow, the semi-automatic bagging machine has proven its worth. Its ability to streamline the packaging process, enhance productivity, and improve product presentation makes it an indispensable asset for businesses across various sectors.

In conclusion, the semi-automatic bagging machine has revolutionized the packaging industry. Its automated features, versatility, and customization options have transformed the way companies package their goods. Whether in the food, pharmaceutical, or automotive industry, these machines provide a reliable and efficient solution to enhance productivity and reduce human error. The paintbrush manufacturing industry, in particular, has witnessed a significant boost in productivity and product presentation since integrating semi-automatic bagging machines into their production line. With their advanced technology, ease of use, and maintenance, these machines are here to stay and continue to shape the future of industrial packaging.

Bagging Machine

“Efficiency and Convenience: Bagging your Paint Brushes Has Never Been Easier with our Automatic and Semi-Automatic Machines”