Industrial Automation Robots Revolutionizing the Garment Industry

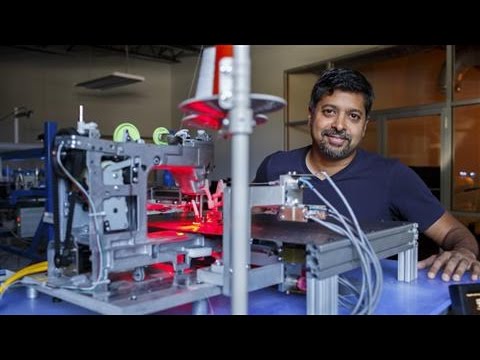

The garment industry has come a long way in terms of production efficiency and quality control. Engineers at SoftWear Automation in Atlanta are at the forefront of this revolution, striving to automate one of the trickiest manufacturing processes: sewing. With the help of industrial automation robots, they are changing the face of garment production as we know it.

The advent of automation in the garment industry has opened up new possibilities and challenges. As a technical engineer closely involved in this project, I am excited to share how automation is transforming the industry and the immense potential it holds for the future.

The garment industry is notorious for its labor-intensive processes, with sewing being one of the most challenging tasks to automate. Traditional sewing methods involve skilled human hands meticulously guiding fabric through a sewing machine, a process that is time-consuming, requires high precision, and is subject to human error. However, with the introduction of industrial automation robots, this cumbersome process is becoming a relic of the past.

At SoftWear Automation, we have developed advanced robotic systems that mimic human-like dexterity and intelligence, creating a paradigm shift in garment manufacturing. These robots are equipped with computer vision technology, machine learning algorithms, and a high degree of adaptability, enabling them to perform intricate sewing tasks with unparalleled precision and speed.

One of the key advantages of industrial automation robots in the garment industry is their ability to eliminate the variability introduced by human operators. With robots, garment manufacturers can ensure consistent quality throughout the production process, minimizing defects and ensuring customer satisfaction. This level of consistency can greatly enhance brand reputation and increase consumer trust in the product.

Moreover, automation robots have the potential to significantly boost production efficiency. Unlike humans, robots do not tire or require breaks, allowing continuous operation round the clock. This means that manufacturers can meet increasing demands without compromising on delivery timelines. By streamlining the production process, companies can reduce costs and improve profitability, making them more competitive in the global market.

Can robots really transform the garment industry? The answer is a resounding yes. Industrial automation robots can bring about a revolution in garment production, transforming a traditional labor-intensive industry into a highly efficient and technologically advanced sector. By automating sewing processes, factories can improve productivity, quality, and safety, creating a win-win situation for all stakeholders involved.

However, the integration of automation robots into the garment industry comes with its own set of challenges. From a technical standpoint, developing robotic systems that can handle a wide range of fabrics, stitches, and patterns is no mean feat. It requires extensive research and development, collaboration with textile experts, and continuous improvement to ensure compatibility with different production requirements.

Another critical challenge lies in the human element. As automation takes over certain tasks, the industry needs to adapt to this technological transformation and reskill its workforce. Rather than seeing robots as a threat to jobs, we must view them as tools that can enhance human capabilities and create new opportunities. Companies should invest in training programs and upskilling initiatives to ensure a smooth transition for their employees.

Looking ahead, the future of industrial automation robots in the garment industry is promising. As technology continues to advance, robots will become more intelligent, versatile, and adept at handling complex sewing tasks. This will open up new possibilities for customization, faster turnaround times, and even more sustainable manufacturing processes.

In conclusion, the engineers at SoftWear Automation in Atlanta are proving that the garment industry is not immune to the wonders of automation. By harnessing the power of industrial automation robots, sewing, one of the trickiest manufacturing processes, is becoming more efficient, consistent, and cost-effective. The transformative potential of automation in the garment industry is immense, and with the right approach, it can revolutionize the way we produce and consume clothing.

Industrial Robot

“Revolutionizing Garment Production: The Impact of Robotics and Industrial Automation”