The Perfect Marriage of Technology and Evolution: The Industrial Robotic Arm

In the vast realm of technology, few innovations have reached the pinnacle of perfection achieved by the human arm. Over millions of years of evolution, nature has fine-tuned this instrument to become the most versatile and adaptable tool known to mankind. However, in recent times, the emergence of industrial robotic arms has taken this concept to a whole new level.

Industrial robotic arms are technological marvels that have revolutionized the manufacturing and automation industry. These mechanical limbs possess the precision, speed, and dexterity required to perform a wide range of tasks. From assembly lines to cutting-edge research laboratories, these robotic arms are transforming the way we work, think, and innovate.

The history of the industrial robotic arm can be traced back to the 1960s when the first robotic arm, aptly named Unimate, was created by George Devol. Unimate, developed for General Motors, paved the way for a new era in industrial automation. This groundbreaking invention marked the beginning of a symbiotic relationship between humans and machines, where human ingenuity and robotic efficiency converged.

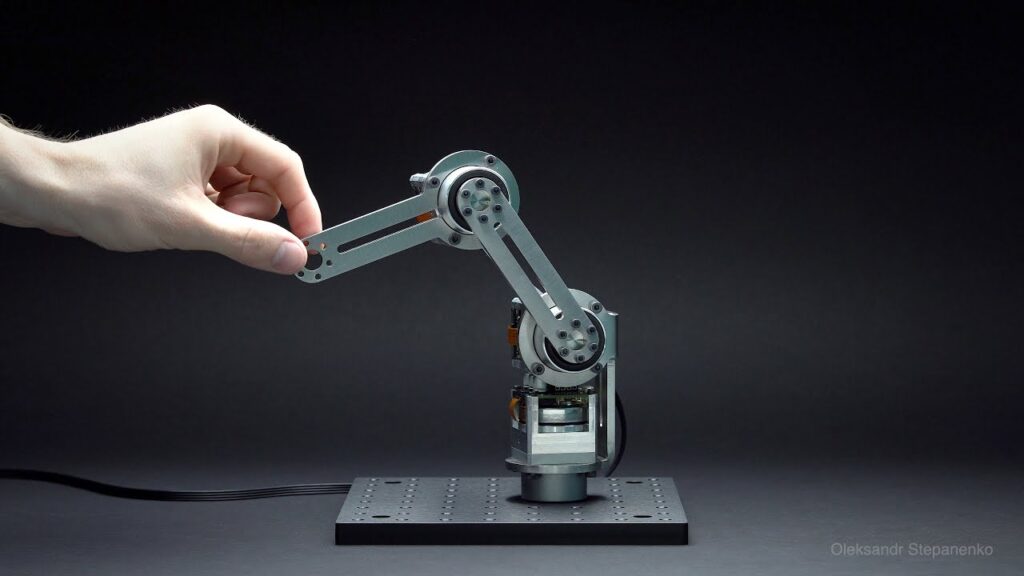

Fast forward to the present day, and we find ourselves surrounded by a plethora of sophisticated industrial robotic arms, each designed to excel in a specific task or industry. One such remarkable example is the ROBOTICS | Miniature 3-axis robotic arm. This compact marvel possesses an exceptional range of motion, allowing it to perform intricate operations with utmost precision. Its small size and lightweight design make it ideal for applications that require flexibility in constrained spaces.

What sets the industrial robotic arm apart from its human counterpart is its ability to work tirelessly without fatigue or error. The human arm, while a marvel of evolution, is limited by its need for rest and the potential for human error. On the other hand, an industrial robotic arm can perform repetitive tasks day in and day out with consistent accuracy, leading to increased productivity and efficiency.

Moreover, the industrial robotic arm brings a new dimension of safety to various industries. In hazardous environments or situations that pose a risk to human operators, these machines can step in and take over. This not only minimizes the chances of accidents but also ensures that workers can be allocated to more skill-dependent tasks, thus maximizing their expertise and potential.

The application of industrial robotic arms extends beyond the confines of manufacturing. These versatile machines have found their way into healthcare, logistics, agriculture, and even creative industries. With advancements in artificial intelligence and machine learning, these robotic arms are learning to adapt to new environments and tasks. They are becoming more intuitive, capable of understanding human intentions, and responding accordingly.

As the adoption of industrial robotic arms continues to grow, there are concerns regarding job displacement. However, history has shown that technology has always created new opportunities. Rather than replacing jobs, these robotic arms are augmenting human skills, leading to the creation of new roles and industries that were previously unimaginable.

In conclusion, the industrial robotic arm represents a perfect marriage between the ingenuity of humans and the advancements of technology. Harnessing the power of evolution, engineers and innovators have created machines that can perform tasks beyond the scope of human capability. From the first robotic arm developed in the 1960s to the cutting-edge models of today like the ROBOTICS | Miniature 3-axis robotic arm, these machines have redefined the way we work and envision the future. As we continue to unlock their potential, the possibilities are endless, and the benefits to humanity immeasurable.

Industrial Robot

“Unleashing the Power of 3-Axis Robotic Arms: Miniature Precision meets Industrial Automation”