Industrial Robots in Manufacturing: Achieving Sustainable Manufacturing with Epson Robots

In today’s fast-paced and environmentally conscious world, businesses are constantly looking for ways to minimize their footprint and adopt sustainable practices. One area where this is particularly crucial is in the manufacturing industry, where automation and robotics play a significant role. With the help of Epson Robots, businesses can achieve sustainable manufacturing while maximizing efficiency and productivity.

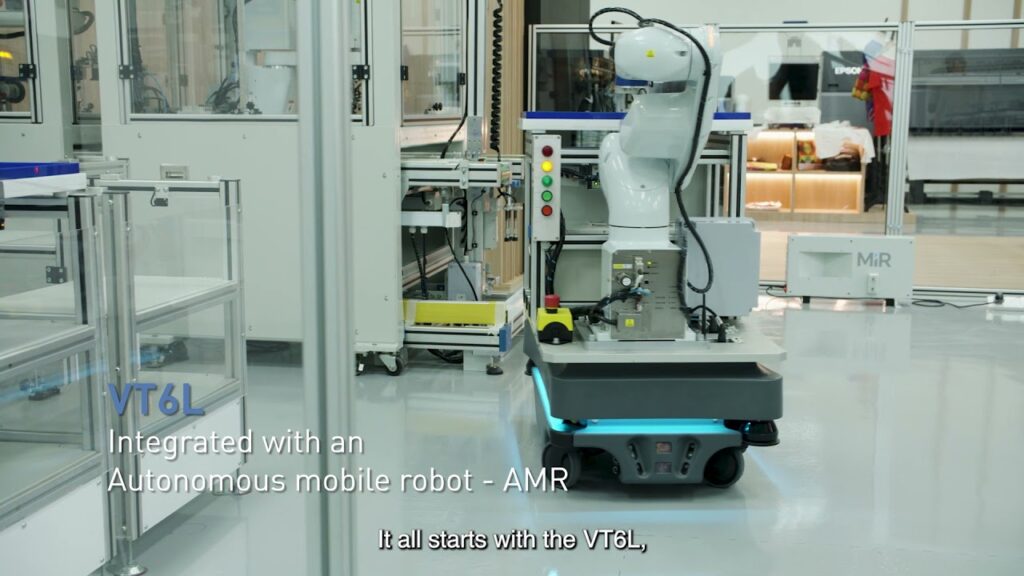

Epson Robots, a leading manufacturer of industrial robots, has revolutionized the manufacturing landscape with their state-of-the-art robotic solutions. These robots not only streamline production processes but also contribute to sustainable manufacturing practices by minimizing waste, reducing energy consumption, and optimizing resource utilization.

One of the key benefits of using Epson Robots in manufacturing is the reduction in material waste. These robots are designed with precision and accuracy, ensuring minimal errors and defects in the manufacturing process. By eliminating the need for human intervention in repetitive tasks, the risk of errors is significantly reduced, leading to a decrease in the number of defective products. This not only saves valuable resources but also minimizes the environmental impact associated with waste disposal.

Furthermore, Epson Robots are equipped with advanced sensing and vision systems that enable them to optimize resource utilization. These robots can detect and measure precisely the amount of raw materials required for each production task, thereby minimizing overuse and waste. By optimizing the use of resources, businesses can significantly reduce their environmental footprint while maximizing their operational efficiency.

Energy efficiency is another crucial aspect of sustainable manufacturing, and Epson Robots excel in this area as well. These robots are designed to operate with minimal energy consumption, ensuring that manufacturing processes are as energy-efficient as possible. By reducing energy consumption, businesses not only save on operational costs but also contribute to the overall goal of reducing greenhouse gas emissions and conserving valuable natural resources.

In addition to their contribution to sustainable manufacturing, Epson Robots offer numerous benefits to businesses in terms of efficiency and productivity. These robots are capable of performing complex tasks with high precision and speed, resulting in faster production cycles and increased output. This allows businesses to meet market demands more efficiently while maintaining superior product quality.

Moreover, the integration of Epson Robots into manufacturing processes can also improve workplace safety. With automation taking over hazardous tasks, the risk of human-related accidents is significantly reduced. This not only ensures the well-being of employees but also minimizes potential disruptions in the production process.

The impact of Epson Robots on the manufacturing industry has been profound, leading to increased adoption and success stories across various sectors. Let’s take a closer look at a real-life case study that showcases the transformative power of these industrial robots in achieving sustainable manufacturing.

Case Study: XYZ Manufacturing Company

XYZ Manufacturing Company, a leading player in the auto parts industry, was facing challenges in meeting environmental regulations and maintaining high-quality production standards. The company’s manual manufacturing processes led to significant material waste, energy consumption, and production inefficiencies.

Recognizing the need for a sustainable manufacturing solution, XYZ Manufacturing Company implemented Epson Robots into their production line. The results were remarkable. The precision and accuracy of these robots not only reduced material waste but also improved product quality and overall efficiency.

By optimizing resource utilization, XYZ Manufacturing Company witnessed a significant reduction in raw material consumption, leading to substantial cost savings. The integration of energy-efficient Epson Robots also resulted in a considerable reduction in energy consumption, helping the company meet its sustainability goals.

The implementation of Epson Robots not only addressed the company’s environmental concerns but also improved productivity and profitability. The automated processes resulted in faster production cycles and increased output, enabling XYZ Manufacturing Company to meet customer demand more efficiently. The enhanced product quality further solidified the company’s reputation in the market.

In conclusion, the use of Epson Robots in manufacturing is a game-changer for businesses looking to achieve sustainable manufacturing practices. These robots not only minimize waste and reduce energy consumption but also optimize resource utilization, resulting in improved efficiency and productivity. The real-life success stories, such as XYZ Manufacturing Company, demonstrate the transformative impact of these industrial robots in the quest for sustainable manufacturing. By embracing Epson Robots, businesses can pave the way for a greener and more prosperous future in the manufacturing industry.

References:

– Epson Robots. (n.d.). Retrieved from [Epson Robots website]

– Sustainable Manufacturing – Epson Robots. (n.d.). Retrieved from [Epson Robots website]

Industrial Robot

“Transforming Manufacturing Through Sustainable Practices: Harnessing the Power of Epson and Industrial Robots”