Automatic Handling Machine Revolutionizes Warehouse Automation

The modernization of warehouse processes and the adoption of new technologies have significantly transformed the logistics industry. One such technology that is revolutionizing warehouse automation is the Automatic Handling Machine (AHM). With its ability to streamline operations and enhance efficiency, AHM is rapidly becoming a game-changer in the world of logistics.

AHM is an automated system that utilizes sophisticated robotic arms and advanced sensors to handle various tasks within a warehouse. These machines are designed to perform a wide range of functions, such as picking and placing items, sorting parcels, loading and unloading trucks, and even packaging goods. With their precision and speed, AHMs have proven to be highly reliable and efficient in executing repetitive tasks.

One company at the forefront of AHM development is 2XL N.V., a Belgian logistics firm specializing in warehouse automation solutions. 2XL N.V. has incorporated AHMs into its operations, revolutionizing the way goods are handled in warehouses. By replacing manual labor with robots, 2XL N.V. has witnessed a significant increase in productivity and a reduction in operational costs.

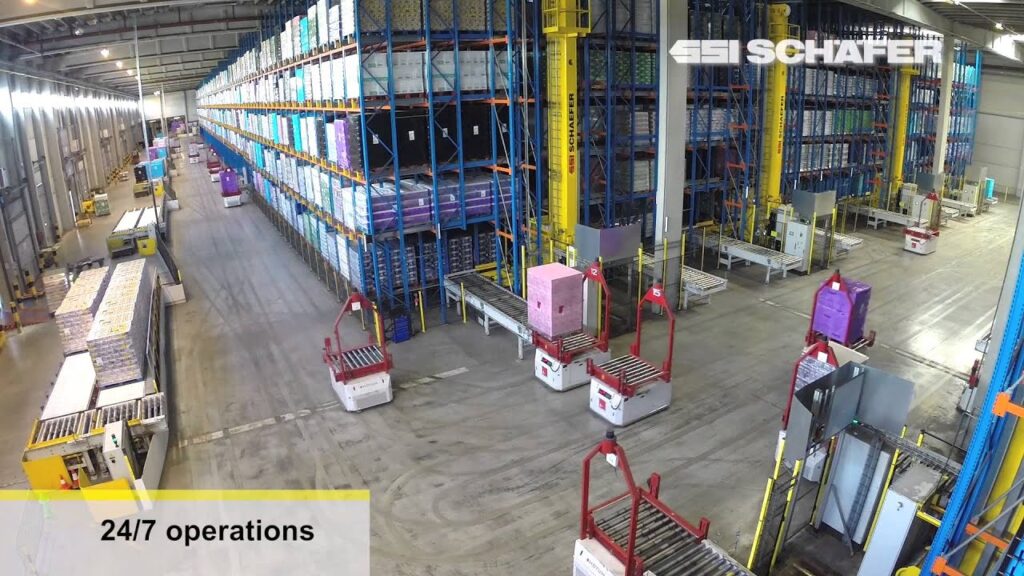

One of the key advantages of AHMs is their ability to work seamlessly with Automated Guided Vehicles (AGVs). AGVs are autonomous vehicles that can navigate through a warehouse using advanced sensors and mapping technologies. By combining the capabilities of AHMs and AGVs, warehouses can achieve a synchronized and optimized workflow.

The integration of AHMs and AGVs has transformed the traditional warehousing process. In the past, workers had to manually retrieve items from storage shelves, scan them, and place them in the appropriate location. This process was time-consuming and prone to errors. With AHMs and AGVs, the entire process is automated. The AHMs are capable of identifying products, picking them up from storage, and placing them on the AGVs for transportation to the desired location. This seamless coordination between machines has resulted in faster order fulfillment and improved accuracy.

Furthermore, AHMs are equipped with advanced sensors that enable them to detect obstacles and avoid collisions. This ensures the safety of both the machines and the workers in the warehouse. The incorporation of cutting-edge technologies, such as artificial intelligence and machine learning, allows AHMs to continuously improve their performance and adapt to changing environments.

The impact of AHMs on warehouse automation extends beyond operational efficiency. These machines also have environmental benefits. By optimizing the space utilization within a warehouse, AHMs help conserve energy and reduce the carbon footprint. Additionally, with their accuracy and precision, AHMs minimize product damage, resulting in reduced wastage and improved sustainability.

The adoption of AHMs is not without its challenges. Implementing such advanced technology requires significant investment, both in terms of capital and training. Companies need to carefully assess their operational requirements and evaluate the cost-benefit analysis before integrating AHMs into their warehouses. However, the long-term benefits of increased efficiency and reduced costs outweigh the initial investment.

As the demand for faster order fulfillment and increased accuracy continues to rise, the role of AHMs in warehouse automation will only become more prominent. Their ability to handle repetitive tasks with precision and speed makes them an indispensable asset in the logistics industry.

In conclusion, the Automatic Handling Machine is revolutionizing warehouse automation. The seamless coordination between AHMs and AGVs has resulted in improved operational efficiency, faster order fulfillment, and enhanced accuracy. With their advanced sensors and robotic arms, AHMs efficiently handle various tasks within a warehouse, replacing manual labor and reducing operational costs. As logistics companies, like 2XL N.V., continue to embrace AHMs, the industry will witness a significant transformation in warehouse operations. The future of warehouse automation is here, and it is driven by the Automatic Handling Machine.

Handling Machine

"Streamlining Warehouse Operations with Advanced Automated Guided Vehicles and Storage Solutions"