Automated Handling of Dairy Products: The Revolutionizing Role of Robots

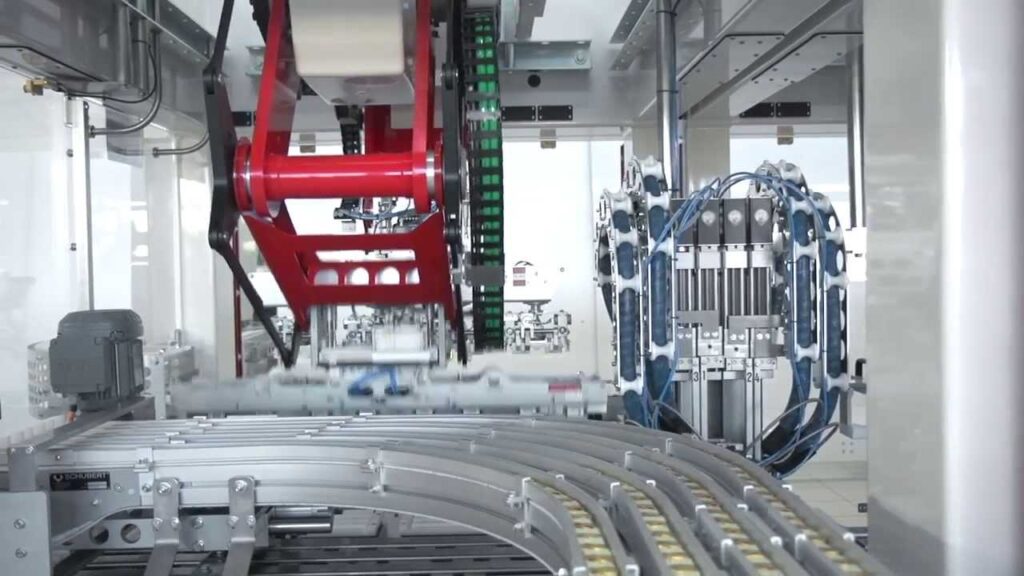

In October 2013, the packaging industry witnessed a major breakthrough when a customer in France received a revolutionary Automatic Handling Machine from Schubert. This state-of-the-art machine transformed the process of packaging butter portion packs, contributing to a significant increase in productivity. With a remarkable speed of packaging 1000 butter portion packs per minute, this game-changing innovation has redefined the way dairy products are handled and packaged.

The adoption of automated handling systems has become crucial in the modern world, where efficiency and productivity are paramount. The advancements in technology have allowed for the creation of highly sophisticated machines, capable of performing complex tasks with remarkable precision and speed. The Automatic Handling Machine supplied to our customer in France is a quintessential example of technological brilliance.

The integration of robotics in the packaging industry has revolutionized the way products are handled, packed, and distributed. These highly intelligent machines, designed by Schubert, have the ability to handle delicate dairy products with utmost care and attention to detail. The accuracy in packaging is unparalleled, ensuring that each portion pack is sealed with precision, maintaining the quality and freshness of the product.

The role of the Automatic Handling Machine in the packaging process cannot be overstated. Through the implementation of innovative technologies such as computer vision and machine learning, these robots are capable of identifying and categorizing butter portion packs with extraordinary efficiency. The machines scan each pack, analyzing its size, shape, and weight to determine the optimal packaging sequence. This level of automation minimizes the risk of human error and ensures that the packaging process is streamlined and error-free.

Moreover, the versatility of the Automatic Handling Machine is truly remarkable. It can handle a wide range of packaging materials and sizes, accommodating different customer requirements. Whether it is small portion packs or larger bulk packaging, this machine can adapt to varying demands with ease, making it a cost-effective solution for businesses in the dairy industry.

The impact of this innovation on the overall production process cannot be underestimated. By automating the handling and packaging of dairy products, businesses can significantly enhance their operational efficiency and productivity. The integration of the Schubert Automatic Handling Machine allows for quick and seamless packaging, reducing the overall production time and enabling businesses to meet deadlines and achieve higher output targets.

In addition to its efficiency, the Automatic Handling Machine also prioritizes food safety and hygiene. The machine is equipped with advanced sensors that ensure the detection and removal of any contaminated or faulty portion packs. This stringent quality control mechanism guarantees that only the finest and safest products reach the end consumer.

The implementation of robotic systems in the packaging industry also has significant environmental benefits. The Automatic Handling Machine minimizes packaging waste by optimizing the use of materials, resulting in a more sustainable packaging process. Furthermore, the reduction in human error and subsequent rework reduces unnecessary resource consumption, ultimately contributing to a greener and more efficient industry.

As we delve into the future of automated handling, it is evident that robotics will continue to play a pivotal role in the packaging industry. The integration of artificial intelligence, machine learning, and computer vision will further enhance the capabilities of these machines, making them invaluable assets for dairy businesses worldwide. The potential for increased productivity, cost savings, and improved product quality is immense.

The journey towards automation in the handling and packaging of dairy products was set in motion with the introduction of the Automatic Handling Machine by Schubert. This innovative solution has paved the way for a more efficient, accurate, and sustainable industry. As we observe the impact it has created within the packaging sector, it becomes evident that robotics is the way forward. Embracing this technology will enable dairy businesses to stay ahead in a highly competitive market, ultimately benefiting both the industry and the consumers.

In conclusion, the integration of the Automatic Handling Machine in the packaging process has brought a revolution to the dairy industry. With its unmatched speed, precision, and versatility, this remarkable innovation has transformed the way dairy products are handled and packaged. By embracing automation and leveraging cutting-edge technologies, businesses can usher in a new era of efficiency, productivity, and quality within the packaging industry. The future is here, and it is automated!

Handling Machine

"Efficient Dairy Product Handling: Robots Efficiently Package Portion Packs into Boxes with Automatic Handling Technology"