Heat Shrinking Machine: A Game-Changer in Wire Heat Shrink Tubing

In today’s fast-paced world, where technology is advancing at an astonishing rate, innovation in various industries is becoming increasingly crucial. One such industry that has greatly benefitted from technological advancements is the manufacturing sector. With the introduction of state-of-the-art equipment and machines, the manufacturing process has become more efficient and streamlined. Among these machines, the Heat Shrinking Machine stands out as a game-changer in the wire heat shrink tubing industry.

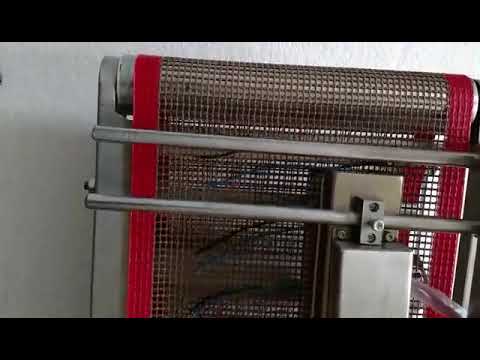

The Heat Shrinking Machine, also known as the Wire Heat Shrinking Sleeves Heating Machine, is a marvel of engineering and automation. It utilizes precise heat to effectively shrink heat shrink tubing, providing a tight and secure fit around wires, cables, and other components. This machine has revolutionized the manufacturing process, making it quicker, more reliable, and cost-effective. Let us delve deeper into this incredible piece of technology and explore its advantages and applications.

First and foremost, the Heat Shrinking Machine ensures precise and consistent heat application, generating reliable results every time. With its cutting-edge temperature control system, it can maintain a stable heat level that is essential for optimal shrinkage. This eliminates the need for manual heat application, reducing the chances of human error and ensuring a uniform shrink on every wire or cable. The result is a professional-looking finish that instills confidence in the end users.

Furthermore, the Heat Shrinking Machine is incredibly versatile and can accommodate a wide range of wire sizes and heat shrink tubing materials. Whether you are working with thin wires or thick cables, this machine can handle it all. Its adjustable settings allow for customization, enabling manufacturers to cater to specific requirements. Additionally, it can work with various heat shrink tubing materials, including polyolefin, PVC, and fluoropolymer, making it suitable for diverse industries such as automotive, aerospace, electronics, and telecommunications.

One of the key advantages of the Heat Shrinking Machine is its efficiency in time and labor management. In traditional shrink wrapping methods, workers had to manually apply heat to the tubing using heat guns or ovens. This process was not only time-consuming but also labor-intensive, often leading to inconsistencies in shrinkage. With the Heat Shrinking Machine, manufacturers can eliminate this bottleneck, streamlining the manufacturing process and significantly reducing production time.

Moreover, the Heat Shrinking Machine enhances the overall durability and protection of wires and cables. By tightly encapsulating them with heat shrink tubing, it safeguards them against moisture, chemicals, abrasion, and other external elements. This is especially crucial in industries where the wires are exposed to harsh environments or subjected to high mechanical stress. The machine ensures a secure and robust connection, prolonging the lifespan of the wires and minimizing the risk of electrical failures.

The applications of the Heat Shrinking Machine are vast and varied. In the automotive industry, it is used to insulate and protect wire harnesses, ensuring proper functioning of the vehicle’s electrical systems. In the aerospace industry, it is employed to secure and shield critical wiring in aircraft, where safety and reliability are paramount. In the electronics industry, it is utilized to encapsulate fragile components and circuitry, providing an added layer of protection. These are just a few examples of the machine’s versatility and adaptability.

In conclusion, the Heat Shrinking Machine has revolutionized the wire heat shrink tubing industry, simplifying and enhancing the manufacturing process. Its precise heat application, versatility, efficiency, and durability make it an indispensable tool for manufacturers across various sectors. With this machine, companies can ensure the highest quality and reliability of their products, ultimately satisfying their customers’ expectations. As technology continues to evolve, it is fascinating to think about the possibilities that lie ahead for the Heat Shrinking Machine and its impact on the manufacturing landscape.

Shrinking Machine

“Efficient Heat Shrinking Machines for Wire Heat Shrink Sleeves and Harness Tubing: A Comprehensive Overview”