Heat Shrinking Machine: Revolutionizing the Packaging Industry

The packaging industry has witnessed a significant revolution over the years, thanks to technological advancements and innovative machinery. One such breakthrough is the heat shrinking machine, which has transformed the way products are packaged and labeled. In this article, we will explore the functionality and benefits of heat shrinking machines, with a particular focus on the small bottle sleeve labeling machine.

Heat shrinking machines have become an indispensable part of the packaging process, with their ability to provide efficient and reliable packaging solutions. These machines utilize the principle of heat to shrink a plastic film or sleeve around a product, creating a tight and secure package. The main advantage of this technology is the ability to wrap products of different shapes and sizes, ensuring a snug fit every time.

The small bottle sleeve labeling machine, equipped with a heat shrinking machine, has proven to be particularly useful for industries dealing with bottled products such as beverages, cosmetics, and pharmaceuticals. This machine not only labels the bottles but also provides a layer of protection, ensuring that the products remain intact during transportation and storage.

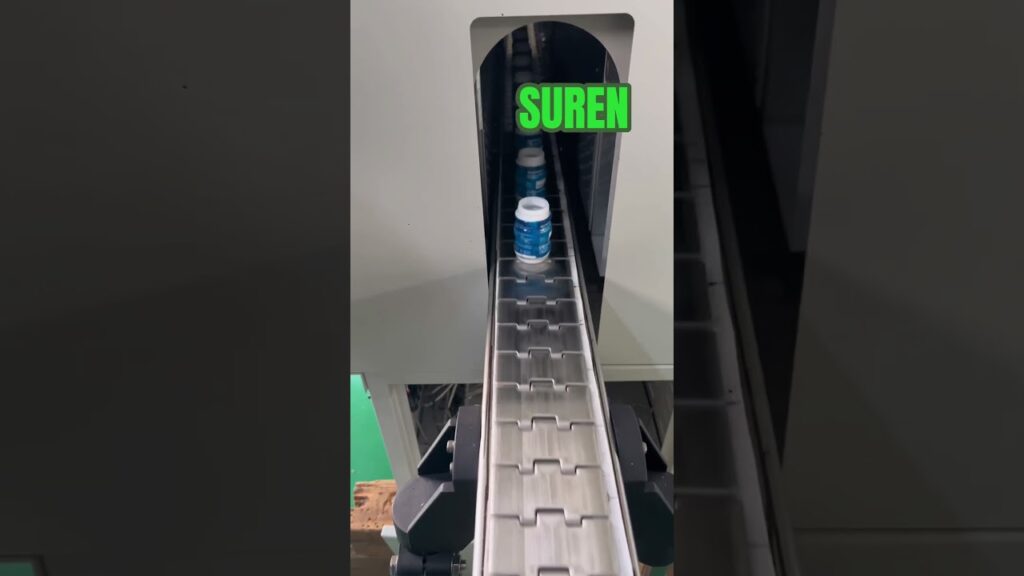

The process begins with the small bottle sleeve labeling machine automatically feeding the bottles onto the conveyer belt. The bottles then move through a labeling station, where a label is applied using an adhesive. Once the label is in place, the bottles proceed to the heat shrinking station, where the heat shrinking machine comes into play.

The heat shrinking machine uses heat to shrink the plastic film around the labeled bottle, conforming it to the shape of the container. This process not only secures the label firmly in place but also provides a tamper-evident seal, ensuring the integrity of the product. The heat shrinking machine operates at the perfect temperature, ensuring that the packaging remains wrinkle-free and aesthetically appealing.

The benefits of utilizing a heat shrinking machine in the packaging process are manifold. Firstly, it enhances the visual appeal of the product, as the tight and seamless shrink-wrap provides a professional and polished look. This becomes crucial for companies looking to create a brand image and stand out from the competition.

Secondly, the heat shrinking technology offers superior protection to the products. The plastic film acts as a barrier against external elements such as moisture, dirt, and UV rays, preventing any damage to the contents. This, in turn, enhances the shelf life of the products, reducing the chances of spoilage and ensuring customer satisfaction.

Furthermore, the heat shrinking machine ensures cost-effectiveness in the packaging process. By automating the labeling and shrinking process, companies save significant labor costs and ensure higher production efficiency. The machines are designed to handle a large volume of products, ensuring a streamlined packaging process with minimal human intervention.

The small bottle sleeve labeling machine with a heat shrinking machine also offers versatility in packaging. With the capability to package bottles of various shapes and sizes, manufacturers have the flexibility to cater to diverse customer needs. This adaptability is particularly beneficial in the fast-paced consumer market, where demands change rapidly.

In conclusion, heat shrinking machines have revolutionized the packaging industry, and the small bottle sleeve labeling machine is a testament to its effectiveness. The ability to automate the labeling and shrinking process, combined with the superior protection and aesthetic appeal it offers, has made it an indispensable tool for industries around the world.

The heat shrinking machine’s impact on the packaging industry is undeniable, as it has transformed the way products are packaged and presented to consumers. With the ever-growing demands for efficiency and reliability, these machines continue to play a vital role in ensuring customer satisfaction and brand success. As technology continues to advance, we can only expect further advancements in the field of packaging machinery, further enhancing the efficiency and effectiveness of heat shrinking machines.

Shrinking Machine

“Efficient Small Bottle Sleeve Labeling and Heat Shrinking Machine: Witness Factory Shooting of Advanced Heat Shrinking Technology”