Motion control is a crucial aspect of industrial robotics, as it defines the precision and accuracy of robot joint movements. In order to improve overall accuracy and utilize the full potential of industrial robots, it is essential to understand the different types of robot joints and their mechanisms. This article aims to shed light on the significance of precise robot joint movements and explore the various types of industrial robots.

Robots have become an integral part of many industries, from manufacturing and assembly lines to healthcare and agriculture. These advanced machines have revolutionized the way tasks are performed, offering increased efficiency, productivity, and cost-effectiveness. However, to fully capitalize on the capabilities of industrial robots, it is imperative to ensure that the joints of these machines are capable of making accurate movements.

The motion control of robot joints involves the planning, monitoring, and execution of movements to achieve a desired position or trajectory. This level of precision is vital in industries where even the slightest deviation can lead to catastrophic consequences. Take, for example, the automotive industry, where robots are used extensively for tasks such as welding, painting, and assembly. In such applications, the precise movements of robot joints are essential for maintaining consistent quality and ensuring a flawless finish.

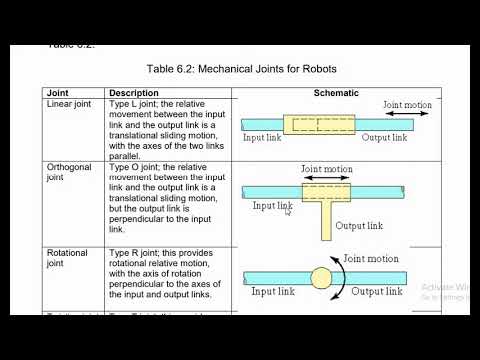

One of the key factors in achieving precise robot joint movements is the mechanical design of the joints themselves. There are various types of joints used in industrial robots, each with its own unique characteristics and advantages. The most common types include revolute joints, prismatic joints, and spherical joints.

Revolute joints, also known as rotary joints, allow rotational movement around a single axis. This type of joint is commonly found in robotic arms and is responsible for providing the necessary flexibility and range of motion. By carefully controlling the rotation of revolute joints, robots can perform intricate tasks with utmost precision.

Prismatic joints, on the other hand, enable linear movement along a single axis. These joints are commonly used in Cartesian robots, where precise linear motions are required for tasks such as material handling and pick-and-place operations. By accurately controlling the extension or retraction of prismatic joints, industrial robots can perform repetitive tasks with high accuracy and repeatability.

Spherical joints, also known as ball joints, offer a combination of rotational and tilting movements. They enable robots to achieve multi-directional flexibility and are commonly found in applications that require a high degree of dexterity, such as assembly tasks involving complex geometries. By precisely controlling the rotational and tilting movements of spherical joints, industrial robots can adapt to various workpieces and perform intricate manipulations.

In addition to the mechanical design of robot joints, the control algorithms and software play a crucial role in achieving precise movements. These algorithms use sensors and feedback mechanisms to monitor the position and orientation of the joints in real-time, allowing for precise adjustment and correction. The advancements in control systems have significantly contributed to the overall accuracy and performance of industrial robots.

The importance of precise robot joint movements goes beyond improving accuracy and performance. It also plays a vital role in ensuring the safety of human workers. Collaborative robots, or cobots, are designed to work alongside humans in shared workspaces. These robots rely on precise joint movements to detect and react to human presence, ensuring safe and efficient collaboration.

In conclusion, motion control and precise robot joint movements are essential in the world of industrial robotics. By understanding the different types of robot joints and their mechanisms, we can optimize the accuracy and performance of industrial robots. The advancements in mechanical design, control algorithms, and software have revolutionized the capabilities of these machines, offering increased efficiency, productivity, and safety. As the demand for automation continues to rise, it is crucial to continue exploring and improving the precision of robot joint movements.

Industrial Robot

Understanding Robot Mechanical Joints and Types of Industrial Robots: Exploring Industrial Robot Joints (PART-1).