The Six Axis Industrial Robot: Exploring the Wrist Axis Motion

In today's fast-paced and technologically advanced world, the use of industrial robotic arms has become increasingly common. These powerful machines, capable of performing a wide range of tasks with precision and efficiency, have revolutionized industries such as manufacturing, automotive, and even healthcare. One key feature of these industrial robots is their ability to move in multiple axes, and in this article, we will delve into the fascinating world of the wrist axis motion of the six-axis industrial robot.

The wrist axis motion refers to the movement of the robot's wrist, which comprises of several axes. In the case of the industrial robot we are discussing today, the wrist consists of axes 4 and 5. These axes play a crucial role in determining the flexibility and maneuverability of the robot arm, allowing it to adapt to various tasks and work in complex environments.

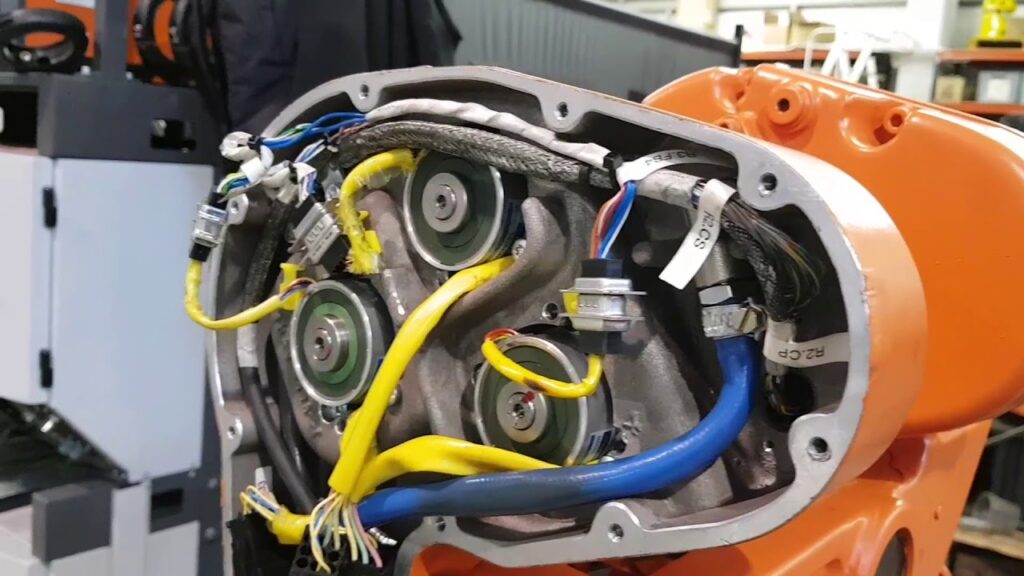

To understand the importance of the wrist axis motion, let us take a closer look at the Inner view of the IRB2400 industrial robot arm. With a payload capacity of 15 kg, this robotic arm is a remarkable example of precision and strength. The robust design of the arm, coupled with the advanced control system, allows it to perform tasks that require high levels of accuracy and control.

The fourth axis of the wrist enables the robot to rotate its wrist horizontally, providing a significant range of motion. This rotational movement allows the robotic arm to reach different points within its workspace, facilitating efficient task execution. Whether it is picking and placing objects, welding intricate parts, or even painting surfaces, the fourth axis plays a vital role in achieving optimum performance.

Moving on to the fifth axis, we encounter yet another remarkable feature of the six-axis industrial robot. This axis enables the robotic arm to tilt its wrist, allowing it to access different angles and positions. The ability to tilt the wrist greatly expands the robot's workspace, making it suitable for tasks that require complex orientations and placements. Coupled with the rotational movement of the fourth axis, the fifth axis provides unparalleled flexibility and adaptability to the industrial robot.

It is worth mentioning that the six-axis industrial robot is not limited to just four and five axes; it also possesses additional axes in its structure. However, for the purposes of this discussion, we will focus on the wrist axes as they are directly responsible for the wrist axis motion and have a significant impact on the robot's overall performance.

The wrist axis motion is a critical aspect of the industrial robotic arm as it enables it to perform precise and complex tasks. Imagine a scenario where this robot is utilized in a factory assembly line, where it is responsible for picking up small components and assembling them efficiently. The ability to rotate and tilt its wrist allows the robot arm to access various areas effortlessly, ensuring that each component is placed correctly and firmly.

Furthermore, the wrist axis motion of the six-axis industrial robot also contributes to its overall safety. With the ability to move with such precision and control, the robot arm can avoid collisions or accidents, reducing the risk of damage to both the machine and its surroundings. This, in turn, makes the work environment safer for humans working alongside these advanced machines.

In conclusion, the wrist axis motion of the six-axis industrial robot is a remarkable feat of engineering. Through the rotation and tilting of its wrist, this robotic arm can perform a wide range of tasks with precision and adaptability. Whether it is in manufacturing, automotive, or healthcare, the industrial robotic arm has proven to be a game-changer in revolutionizing industries worldwide. As technology continues to advance, we can only expect even more impressive developments in the field of industrial automation.

Industrial Robot

"Unveiling the IRB2400: A Comprehensive Look into the Inner Workings of an Industrial Robotic Arm"