Bulk Material Handling Machine: Revolutionizing the Way Industries Handle Dry Bulk Solids

Introduction

In the realm of industrial processes, the efficient handling of bulk materials plays a pivotal role in ensuring smooth operations and cost-effectiveness. Over the years, advancements in technology have led to the development of innovative solutions that aim to enhance the handling of dry bulk solids, both in powdered and granular forms. Amongst these process technology solutions, Bulk Material Handling Machines have emerged as a game-changer, revolutionizing the way industries handle their materials.

Bulk Material Handling Solutions: A Crucial Need

Before delving deeper into the significance of Bulk Material Handling Machines, it is imperative to understand why effective handling of bulk materials is of utmost importance in various industries. Whether it is the pharmaceutical sector, food processing industry, mining and mineral extraction, or construction activities, large quantities of dry bulk solids need to be moved, stored, and processed at every stage.

Traditionally, manual labor was employed to carry out these tasks, leading to several challenges, including inconsistencies in material flow, increased risk of accidents, inefficient use of manpower, and compromised quality control. Moreover, the manual handling of bulk materials was a time-consuming process, often resulting in delays and hindered productivity. To address these issues, Bulk Material Handling Solutions came into existence, automating the entire process and offering a wide range of benefits.

Bulk Material Handling Machines: The Backbone of Efficient Operations

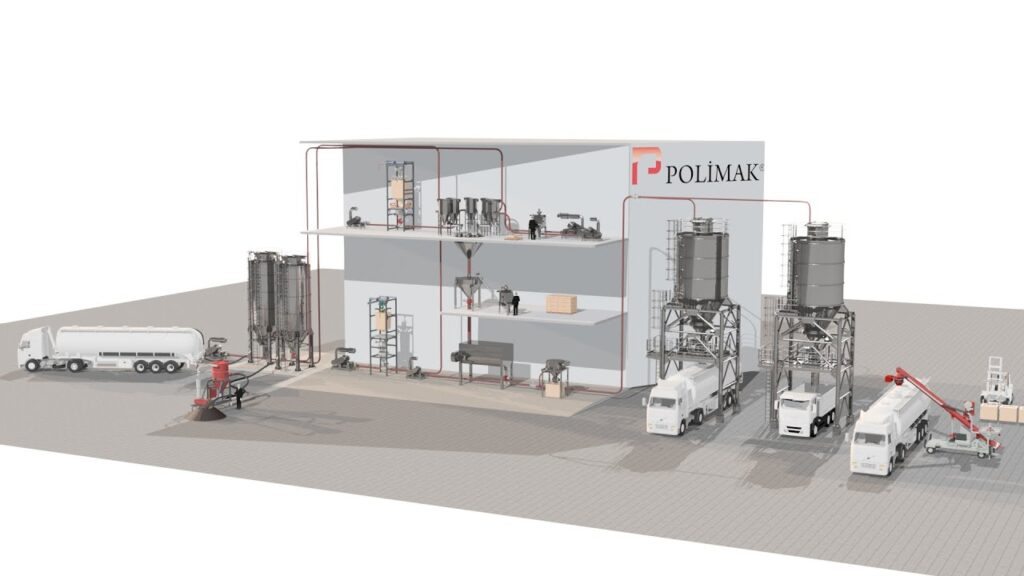

A Bulk Material Handling Machine is a mechanical system specifically designed to handle, store, and transport large quantities of bulk materials. These machines utilize a variety of technologies, such as conveyor belts, bucket elevators, automated storage and retrieval systems, and pneumatic systems, to streamline the flow of materials and optimize production processes.

One of the key advantages of Bulk Material Handling Machines is their ability to handle different types of dry bulk solids, including powders, granules, flakes, and pellets, without compromising on their integrity. This versatility makes them indispensable in a myriad of industries, enabling the seamless movement of materials from one point to another, be it within a facility or across multiple locations.

Thanks to the advancements in technology, modern Bulk Material Handling Machines are equipped with state-of-the-art features, such as automated sorting, weighing, and packaging capabilities. These machines not only ensure the precise measurement and distribution of materials but also minimize the chances of human error and mitigate product contamination risks. By eliminating the need for manual intervention, Bulk Material Handling Machines enhance worker safety and reduce labor costs, allowing industries to allocate their resources efficiently.

Moreover, the integration of bulk material handling systems with smart sensors and real-time monitoring solutions allows for enhanced visibility and control over the entire process. Industries can now monitor material flow, identify bottlenecks, and optimize their operations accordingly, leading to improved efficiency, reduced downtime, and increased overall productivity.

Case Study: XYZ Corporation's Experience

To gain a deeper insight into the impact of Bulk Material Handling Machines, let us consider the case of XYZ Corporation, a leading player in the chemical industry. Prior to implementing bulk material handling solutions, XYZ Corporation faced significant challenges in maintaining the quality and consistency of their powdered raw materials. Manual handling resulted in material contamination, leading to rejected batches and increased wastage.

By investing in a state-of-the-art Bulk Material Handling Machine, XYZ Corporation witnessed a remarkable transformation in their operations. The machine automated the entire process of material handling, ensuring precise measurements, segregation, and timely delivery to the production lines. Not only did this lead to a substantial reduction in rejected batches, but it also minimized material loss and enhanced product quality. The company experienced a significant increase in production efficiency, translating into higher profits and customer satisfaction.

Conclusion

In conclusion, Bulk Material Handling Machines have revolutionized the way industries handle dry bulk solids, providing efficient and cost-effective solutions. These machines not only automate the material handling process but also ensure the integrity and quality of the materials, thereby enhancing production efficiency and minimizing operational risks. With continuous advancements in technology, Bulk Material Handling Machines are set to play an increasingly instrumental role in various industries, driving innovation and enabling seamless operations. As industries continue to strive for sustainability and improved operational excellence, investing in Bulk Material Handling Solutions will undoubtedly be a step in the right direction.

Handling Machine

"Efficient Solutions for Handling Bulk Materials: Maximizing Productivity and Streamlining Operations"