### Industrial Automation Robots: Revolutionizing the Engine Assembly Process

In the fast-paced world of manufacturing, every second counts. Efficiency, precision, and reliability are paramount, especially when it comes to producing complex machinery like engines. The key to achieving these goals lies in the implementation of cutting-edge technology, such as industrial automation robots. These advanced machines, like the ones provided by FANUC Robot Industrial Automation, have revolutionized the engine assembly process, making it faster, more accurate, and significantly more productive.

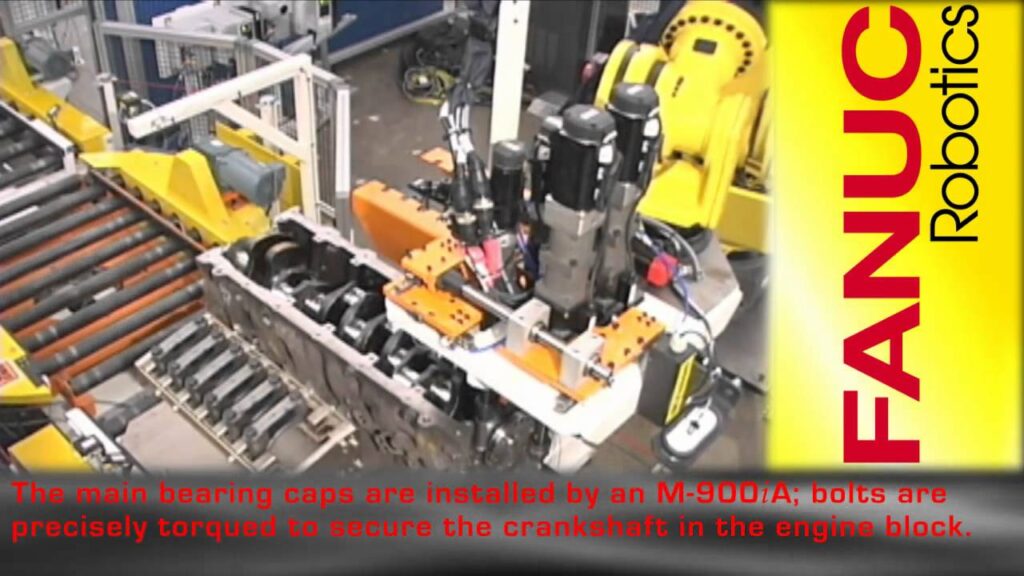

Picture this: a state-of-the-art production line where multiple coordinated robots work tirelessly to piece together an engine with meticulous precision. This innovative approach to engine assembly has become a reality thanks to FANUC Robot Industrial Automation and its array of industrial automation robots.

Industrial automation robots have completely transformed the manufacturing landscape by automating labor-intensive tasks and replacing them with highly efficient machine labor. This not only eliminates the potential for human error but also greatly increases the overall productivity of the assembly process.

The video showcasing FANUC robots in action is truly remarkable. These robots work seamlessly together, flawlessly executing each step of the engine assembly process. With their unparalleled speed and accuracy, FANUC robots ensure that each engine component is precisely placed, tightened, and secured, guaranteeing optimal performance and reliability.

One of the most impressive aspects of these robots is their ability to communicate and synchronize their movements. They seamlessly transfer parts between one another, each robot completing its assigned task without delay. This level of coordination and collaboration is truly awe-inspiring and demonstrates the incredible advancements in robotic technology.

The benefits of using industrial automation robots in the engine assembly process are manifold. Firstly, the speed at which these robots operate vastly surpasses that of human workers. This leads to a substantial increase in production output and allows manufacturers to meet demand effectively.

Secondly, the precision with which these robots work ensures accurate assembly every time. This greatly reduces the likelihood of defects and minimizes the need for rework or repairs. The result is a higher quality product, which, in turn, boosts customer satisfaction and brand reputation.

Additionally, the implementation of industrial automation robots in the engine assembly process leads to significant cost savings. The initial investment in these machines may be substantial, but the long-term benefits far outweigh the expense. With increased productivity and decreased labor costs, manufacturers can allocate resources more efficiently and ultimately enhance their bottom line.

Looking to the future, it is clear that industrial automation robots will continue to shape the manufacturing industry. Their unmatched speed, precision, and efficiency make them indispensable for companies striving to stay competitive in an ever-evolving market. As technology advances, we can expect even more sophisticated robots to take center stage, further optimizing the engine assembly process and driving manufacturing to unprecedented heights.

In conclusion, the video showcasing FANUC Robot Industrial Automation and its industrial automation robots is a testament to the incredible potential of this technology. By revolutionizing the engine assembly process, FANUC robots have set a new standard for efficiency and precision in manufacturing. As these robots become more prevalent, we can expect the industry to experience significant advancements in productivity, quality, and cost savings. The era of industrial automation robots has arrived, and it is poised to shape the future of manufacturing as we know it.

Industrial Robot

“Efficient and Precise Engine Assembly Automation with Robotic Technology”