Plastic Bagging Machine: The Unbeatable Solution for Productivity and Commercial Efficiency

The manufacturing industry is a constantly evolving landscape, with new technologies and innovations emerging every day. Amidst this fast-paced industry, one solution has stood the test of time and proven its superiority when it comes to productivity and commercial efficiency – the Plastic Bagging Machine.

With its advanced design and cutting-edge features, the Plastic Bagging Machine has revolutionized the way products are packaged, making it an indispensable tool for businesses of all sizes. In this article, we will explore the unmatched capabilities of the Plastic Bagging Machine and delve into its role in streamlining production processes.

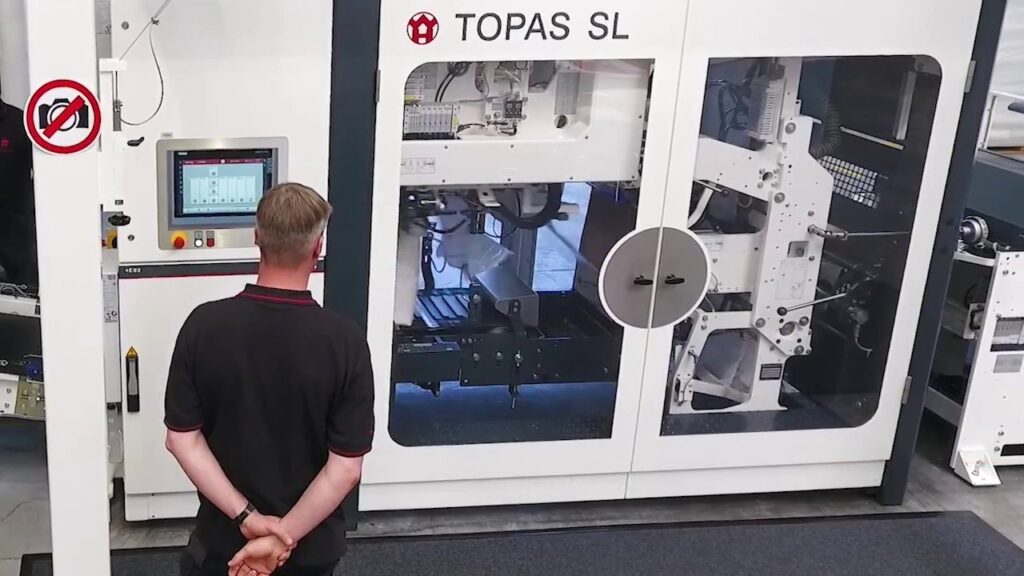

The Plastic Bagging Machine, also known as the Form-Fill-Seal (FFS) system, is a technological marvel that seamlessly integrates bagging, filling, and sealing operations into a single automated process. Developed by W&H, a leading company in Bagging Expertise, this system has become the gold standard in the packaging industry.

Gone are the days where bagging was a labor-intensive task. The FFS system eliminates manual bagging, significantly reducing the time and effort required to package products. This increased automation translates to higher productivity and allows businesses to meet their production quotas effortlessly. The FFS system operates with remarkable precision and speed, ensuring that products are packaged with consistency and efficiency, even in high-volume scenarios.

One of the key advantages of the Plastic Bagging Machine is its versatility. It can handle a wide range of product types, sizes, and materials, making it a valuable asset for industries ranging from food and beverages to pharmaceuticals and consumer goods. Whether it's powders, grains, liquids, or even irregularly shaped items, the FFS system can handle it all with ease. This adaptability eliminates the need for multiple packaging machines, saving businesses valuable floor space and capital investment.

Moreover, the FFS system is designed to optimize material usage. By precisely controlling the amount of material used for packaging, it minimizes waste and reduces operating costs. This not only benefits the environment but also improves the bottom line for businesses. The Plastic Bagging Machine ensures that each bag is accurately formed and filled, resulting in minimal product loss or damage during the packaging process.

In addition to its exceptional productivity and material efficiency, the FFS system offers superior product protection. The machine creates air-tight sealed bags, safeguarding the contents from external contaminants, moisture, and tampering. This level of protection enhances product quality and extends shelf life, two factors that are vital for customer satisfaction and brand reputation.

To further illustrate the unparalleled capabilities of the Plastic Bagging Machine, let us consider a case study. A leading food manufacturing company, struggling with inefficient packaging processes, adopted the FFS system. The results were astounding. The company witnessed a 30% increase in packaging speed, allowing them to meet growing market demands seamlessly. Additionally, the FFS system reduced material waste by 20%, resulting in substantial cost savings and improved sustainability. This success story is just one example of how the Plastic Bagging Machine can transform businesses.

As technology continues to advance at a rapid pace, we can expect the Plastic Bagging Machine to evolve further, catering to the ever-changing needs of the industry. The integration of Artificial Intelligence (AI) and Machine Learning (ML) capabilities holds great promise for the future of the FFS system. Imagine a machine that can analyze production data in real-time, identify areas for improvement, and adjust its settings autonomously to achieve optimal performance. This will undoubtedly maximize productivity and enhance commercial efficiency even further.

In conclusion, the Plastic Bagging Machine, specifically the FFS system by W&H, is the epitome of productivity and commercial efficiency in the packaging industry. Its unmatched capabilities, including automation, versatility, material efficiency, and product protection, make it an indispensable tool for businesses worldwide. As the industry continues to evolve, the Plastic Bagging Machine will continue to lead the way in revolutionizing packaging processes, driving growth, and ensuring customer satisfaction.

*Note: This article is for informational purposes only and does not endorse any specific brand or company. The references to the products mentioned are for illustrative purposes only and are not meant to promote or advertise any particular product.

Bagging Machine

"Efficient Bagging System: From Product Silo to Ready-To-Ship Pallet - FFS Solution by Experts"