The role of digital transformation in today’s business landscape cannot be understated. With the outbreak of COVID-19, companies around the world are realizing the urgent need to adapt and improve their operations through technological advancements. This article will explore how digital transformation is crucial to businesses, particularly in the context of industrial robot manufacturers.

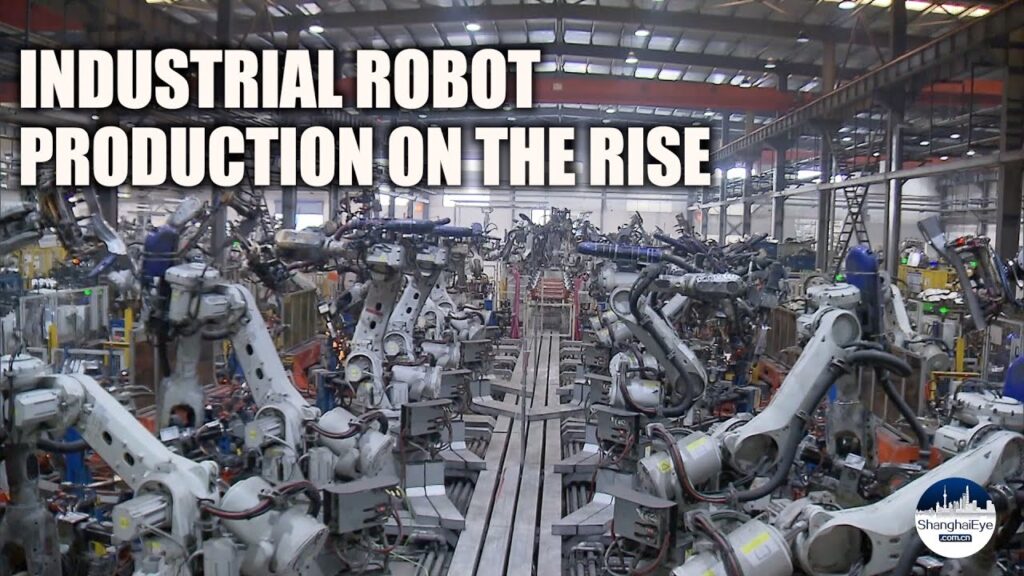

China’s industrial robot production has experienced a surge in recent years, with the widespread use of artificial intelligence (AI) further propelling this growth. As companies strive to increase efficiency, reduce costs, and improve productivity, the adoption of industrial robots has become a strategic imperative.

In the face of the pandemic, industries across the board have faced unprecedented challenges. Supply chain disruptions, labor shortages, and the need for social distancing have all taken their toll on businesses worldwide. This is where digital transformation comes into play.

Industrial robot manufacturers have capitalized on the benefits of digital transformation to not only survive, but thrive, amidst these challenges. Through the integration of AI, robotics, and data analytics, these manufacturers are revolutionizing their operations, yielding significant advantages.

One of the primary benefits of digital transformation is the automation of processes. This allows for the seamless execution of tasks that were previously time-consuming and labor-intensive. By leveraging industrial robots equipped with AI, manufacturers can optimize production lines, resulting in faster and more accurate output. This not only increases efficiency, but it also enhances quality control by minimizing human error.

Additionally, digital transformation enables effective remote monitoring and predictive maintenance. With the capabilities provided by IoT (Internet of Things) technologies, manufacturers can track the performance and health of their industrial robots in real-time. This proactively identifies potential issues, facilitating timely maintenance and reducing downtime. As a result, productivity levels are maximized, minimizing costs and maximizing profitability.

The use of AI in industrial robots also plays a crucial role in adaptive decision-making. With the ability to analyze vast amounts of data, these robots can quickly adjust their actions based on changing circumstances. This agility is particularly crucial in uncertain times, as it allows manufacturers to adapt to market demands and disruptions rapidly. It also enables better resource allocation and inventory management, avoiding bottlenecks and ensuring optimal utilization of available resources.

Moreover, digital transformation enhances collaboration and communication within and across organizations. By leveraging cloud-based platforms and advanced communication tools, manufacturers can seamlessly connect with their suppliers, customers, and partners. This facilitates real-time information sharing, enabling agile decision-making and reducing lead times. Furthermore, it fosters cross-functional collaboration, breaking silos, and facilitating innovation.

The benefits of digital transformation are not limited to internal operations; they also expand to customer interactions. Through the adoption of digital technologies, manufacturers can offer personalized and responsive customer experiences. For instance, AI-powered chatbots can provide customers with immediate assistance, addressing queries and concerns promptly. This not only enhances customer satisfaction but also drives customer loyalty and repeat business.

As the world navigates through the challenges brought about by COVID-19, it is evident that digital transformation is no longer optional but essential for businesses. Industrial robot manufacturers, in particular, stand to gain significant advantages from embracing this transformation.

China’s industrial robot production surge is a testament to the country’s understanding of this imperative. By harnessing the power of AI and advanced robotics, Chinese manufacturers have elevated their production capabilities to new heights. This has positioned them as global leaders in the industry, with their products being sought after worldwide.

In conclusion, digital transformation has become crucial to industrial robot manufacturers, especially in the context of the current global landscape affected by COVID-19. Through the integration of AI, robotics, and data analytics, manufacturers can revolutionize their operations, increasing efficiency, reducing costs, and improving productivity. As China’s industrial robot production surges, it is clear that digital transformation is the way forward for businesses seeking to thrive in the new normal. The benefits are numerous, from automation and remote monitoring to adaptive decision-making and enhanced collaboration. With digital transformation, industrial robot manufacturers have the potential to not only weather the storm but to thrive in these challenging times.

Industrial Robot

“Revolutionizing China’s Industrial Sector: The Surge of AI Utilization in Industrial Robot Production”