Robotic technology has witnessed remarkable advancements in recent years, revolutionizing various industries and manufacturing processes. One crucial aspect of these innovations lies in the arm configurations of industrial robots. In this article, we will delve into the types of robot arm configurations in robotics and explore their advantages.

Robotics has come a long way since its inception, and today, we witness a wide range of industrial robots with different arm configurations. Each configuration possesses unique features and is designed to cater to specific applications. Let’s delve into the various types of robot arm configurations:

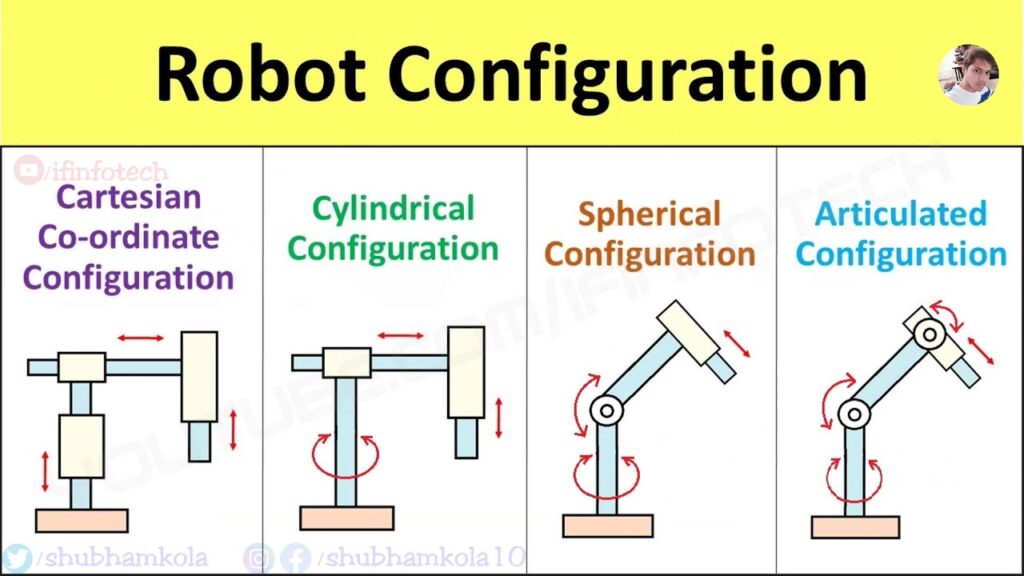

1. Cartesian Coordinate Robots:

Cartesian robots, also known as rectilinear or gantry robots, are characterized by three linear joints located at right angles to each other. Their arm movement is along the X, Y, and Z-axis, allowing them to move in a Cartesian system. These robots are widely used in applications requiring precise and repetitive movements, such as assembly lines or pick-and-place operations.

2. Cylindrical Robots:

Cylindrical robots are equipped with a rotary joint at the base, enabling them to rotate along the vertical axis. Their arm consists of a prismatic joint that allows linear movement along the horizontal axis. With this configuration, cylindrical robots excel in operations requiring extended reach and rotational movements, making them ideal for tasks such as arc welding, machine loading, and unloading.

3. Articulated Robots:

Articulated robots are the most common type of robot arm configuration. They mimic the movement of a human arm, with rotary joints providing articulation at each segment. These joints enable a wide range of movements, allowing articulated robots to perform complex tasks with precision. The versatility of these robots makes them suitable for applications like painting, welding, and material handling.

4. Spherical Robots:

Spherical robots, also referred to as polar robots, feature a spherical work envelope. These robots have a base that rotates along the vertical axis, similar to cylindrical robots. Additionally, they have a shoulder joint that allows movement in the horizontal plane. Spherical robots are commonly used in applications requiring high-speed assembly, such as electronics manufacturing.

5. SCARA Robots:

SCARA stands for Selective Compliance Assembly Robot Arm. These robots are characterized by two parallel rotary joints and one prismatic joint that provides linear motion. The design of SCARA robots allows them to perform tasks with speed and precision, making them ideal for assembly operations, material handling, and high-speed pick-and-place applications.

Now that we have explored the different types of robot arm configurations, let’s examine their advantages:

– Enhanced Precision: Each arm configuration is optimized for specific applications, ensuring precise and accurate movements. This precision results in improved production quality and reduces the possibility of errors.

– Increased Efficiency: Industrial robots equipped with the appropriate arm configuration can perform repetitive tasks at a higher speed, reducing production time and boosting overall efficiency. These robots can operate around the clock, allowing manufacturers to meet tight deadlines.

– Versatility: With the diverse range of robot arm configurations available, industries can leverage robots for an array of applications. Whether it is welding, material handling, or assembly, there is a suitable arm configuration to meet the needs of every task.

– Worker Safety: By deploying robots for tasks that involve hazardous environments or heavy lifting, companies can ensure the safety of their workforce. Robots can effectively handle dangerous materials or operate in high-risk areas, minimizing the risk of accidents and injuries.

– Cost Savings: Implementing industrial robots with the appropriate arm configuration can lead to significant cost savings in the long run. These robots can perform tasks faster and with greater accuracy, reducing waste and optimizing resource utilization.

In conclusion, the world of robotics has witnessed remarkable developments in terms of industrial robot arm configurations. Each configuration, be it Cartesian coordinate, cylindrical, articulated, spherical, or SCARA, brings its own advantages to the table. These arm configurations have revolutionized various industries, enhancing precision, efficiency, versatility, worker safety, and cost savings. As technology progresses, we can expect further advancements in robot arm configurations, unlocking new possibilities for automation in diverse sectors.

Industrial Robot

“Exploring Various Robot Configurations: Cartesian, Cylindrical, Articulated, Spherical, SCARA and Beyond: Understand Different Types of Industrial Robots”