Robotic Arms Paving the Way for Precision in Industrial Settings

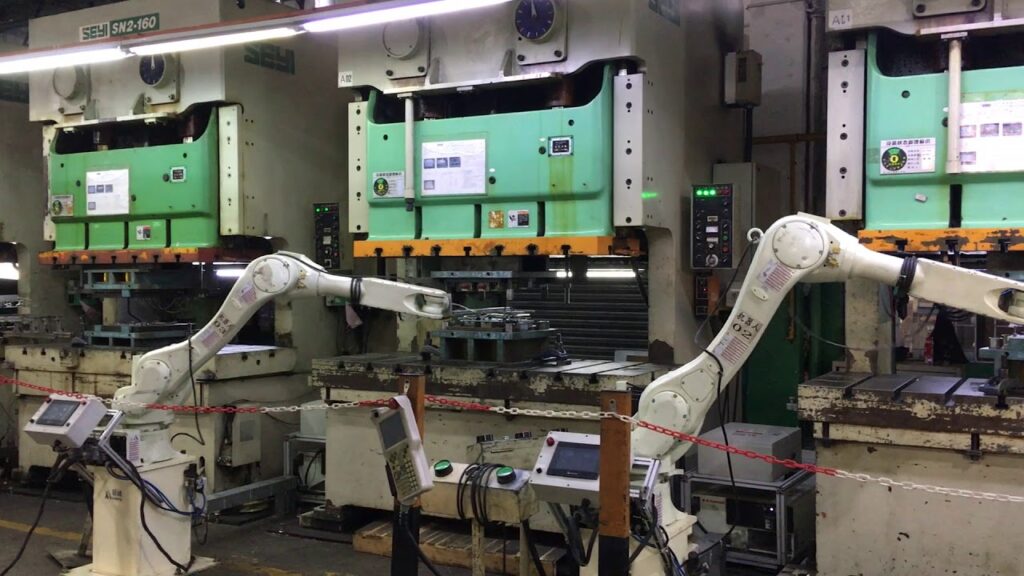

In recent years, technological advancements have revolutionized various industries, and one sector that has particularly witnessed the profound impact of automation is precision manufacturing. With the advent of Industrial Robotic Arms, the landscape of machine shops has been completely transformed, enabling a seamless fusion of human expertise and machine precision. A YouTube video recently showcased a glimpse of these robotic arms working alongside workers in a precision machine shop, and it is truly a sight to behold.

The video captures the essence of innovation and progress in the manufacturing world. As we delve deeper into this compelling footage, it becomes evident that automation is not replacing human workers but rather complementing their abilities. The Industrial Robotic Arms showcased in the video exhibit immense dexterity and efficiency, performing complex tasks with utmost precision and accuracy.

One aspect that stands out about these robotic arms is their versatility. They are equipped with a wide range of tools and can effortlessly switch between tasks, regardless of their complexity or intricacy. From drilling and cutting to welding and polishing, these robotic arms handle every step of the manufacturing process flawlessly, thereby reducing the margin for error and improving overall quality.

Industrial Robotic Arms not only boost productivity but also enhance workplace safety. By taking over hazardous or repetitive tasks, they minimize the risk of workplace accidents and injuries. Workers can now focus on overseeing operations, troubleshooting, and utilizing their skills for specialized tasks that require human intuition and decision-making. It’s a win-win situation for both workers and businesses alike.

As a technical engineer closely associated with the precision manufacturing industry, I can vouch for the immense benefits that Industrial Robotic Arms bring to the table. Incorporating these advanced machines into our machine shops has resulted in a significant increase in efficiency while maintaining the highest standards of quality. The precision and consistency demonstrated by these robotic arms are unparalleled, and they truly are a game-changer.

From an economic standpoint, the adoption of Industrial Robotic Arms proves to be a lucrative investment for companies. While the initial cost may be substantial, the long-term advantages outweigh the initial expenses. These machines work tirelessly around the clock and reduce labor costs considerably. They can operate non-stop and handle tedious tasks with unwavering accuracy, resulting in a boost in production capacity. Moreover, with the capability to work in tandem with human workers, Industrial Robotic Arms create a collaborative environment that fosters innovation and efficiency.

Looking ahead, the integration of Industrial Robotic Arms in precision manufacturing is only set to accelerate. As technology advances further, we can expect even more sophisticated models that outperform their predecessors. The possibilities are limitless, with advancements in machine learning and artificial intelligence paving the way for intelligent robotic arms capable of adapting to dynamic environments seamlessly.

Despite all the advantages and potential of Industrial Robotic Arms, it is crucial to acknowledge the need for skilled human workers who possess the expertise to operate, program, and maintain these machines. The symbiotic relationship between humans and robots is crucial for the smooth functioning of the precision manufacturing industry. The workers in the YouTube video exemplify this harmony, working alongside the robotic arms with finesse and competence.

In conclusion, the YouTube video providing a glimpse of robotic arms working alongside workers in a precision machine shop confirms the transformative power of automation in the industrial sector. Industrial Robotic Arms have ushered in an era of unparalleled precision, efficiency, and workplace safety. Their ability to seamlessly execute complex tasks while working in harmony with human workers is a testament to the progress we have made. As we look to the future, it is evident that Industrial Robotic Arms will continue to shape the landscape of precision manufacturing, pushing boundaries and setting new standards of excellence.

Industrial Robot

“Enhancing Efficiency: Exploring the Capabilities of Industrial Robotic Arms for Optimized Manufacturing Processes”