Introduction:

Learn about the high-end technology behind Model YX-LP1000, an internal structure of liquid pouch packing machine for drinking water packaging equipment and electric wire. With this video, you can get a closer look at the machine’s intricate design and how it ensures quality and consistency in every pouch being packaged.

Video Content:

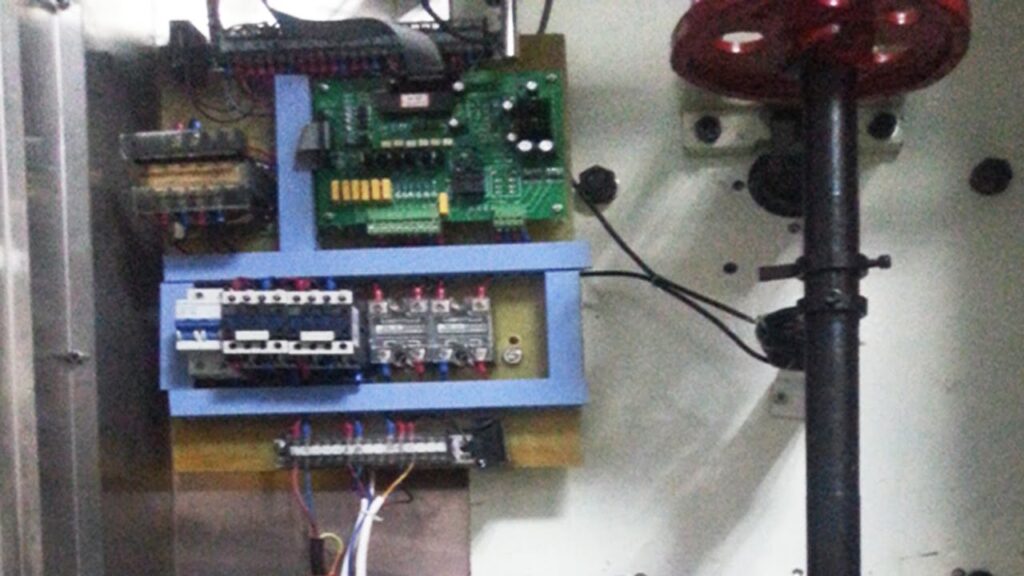

YX-LP1000 boasts of top-notch features that are necessary to keep up with the ever-changing demands of the industry. From the feeding system to the heat-sealing mechanism, this machine utilizes advanced technology to ensure accurate and efficient packing.

The internal structure of this liquid pouch packing machine features a high-speed filling system that can fill up to 50-70 bags per minute. It also has a reliable weighing system that guarantees precise measurements to ensure that every pouch contains the right amount of liquid. You’ll learn that the machine can separate the film roll’s inner and outer layers for a more stable and superior-quality pouch.

This video will provide you with a comprehensive guide to YX-LP1000’s internal structure, including the use of an ultrasonic sensor to detect any inconsistencies in the pouch sealing process, ensuring that each pouch is correctly sealed and safe from any possible leaks.

Conclusion:

In conclusion, Model YX-LP1000 is a reliable and efficient machine that can produce up to 80 pouches per minute. It is designed to handle a wide variety of liquid-based products with ease, including drinking water and electric wires. With this video, you can get an in-depth look at the machine’s features and learn how it can take your packaging process to the next level.

Tags and Keywords:

Internal structure of liquid pouch packing machine, drinking water packaging equipment, electric wire, filling system, weighing system, heat-sealing mechanism, ultrasonic sensor, high-speed, superior-quality pouches, reliable, efficient, consistent, precise, advanced technology.

Hashtags:

#liquidpouchpackingmachine #waterpackagingequipment #electricwire #packagingprocess #advancedtechnology