Title: Injection Molding Production of Cable Ties - Fast and Cost-Effective Solution

Introduction:

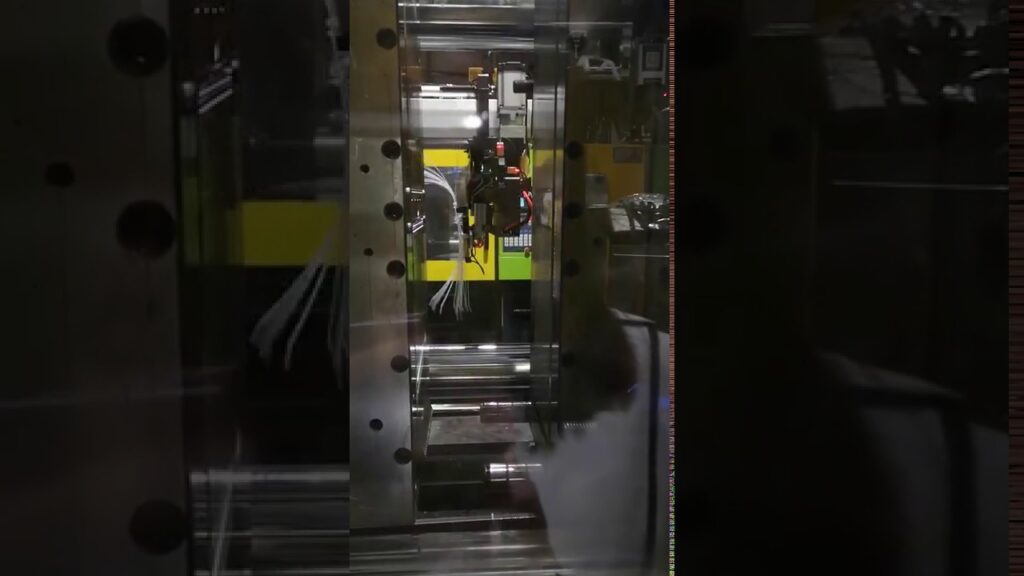

If you are looking for a fast and cost-effective solution for cable ties production, injection molding might be the right method for you. This video will provide you with an in-depth understanding of the injection molding process and how it can be used to produce high-quality cable ties efficiently.

Video Content:

The injection molding technique involves the use of multi-cavity molds to produce cable ties. The plastic material is melted and injected into the molds, which are then cooled to form the final product. This process is highly automated and can produce thousands of cable ties in a short amount of time.

Injection molding production of cable ties is a cost-effective solution that results in low waste and high accuracy. The use of multi-cavity molds reduces material waste, and the automated process ensures consistency in production. The fast production time also reduces labor costs and results in a faster time-to-market.

The quality of the cable ties produced through injection molding is also high due to the accuracy of the molds. The finished product has a high level of detail and is consistent in size and shape. This results in a more reliable and secure application of the cable ties.

Overall, injection molding is an excellent choice for cable tie production, resulting in a fast, cost-effective, and high-quality solution.

Tags and Keywords:

cable ties, injection molding, production, cost-effective, high-quality, multi-cavity molds, automation, accuracy, time-to-market, waste reduction, reliable, secure.

Hashtags:

#cableties #injectionmolding #production #costeffective #highquality #multicavitymolds #automation #accuracy #timetomarket #wastereduction #reliable #secure