Introduction:

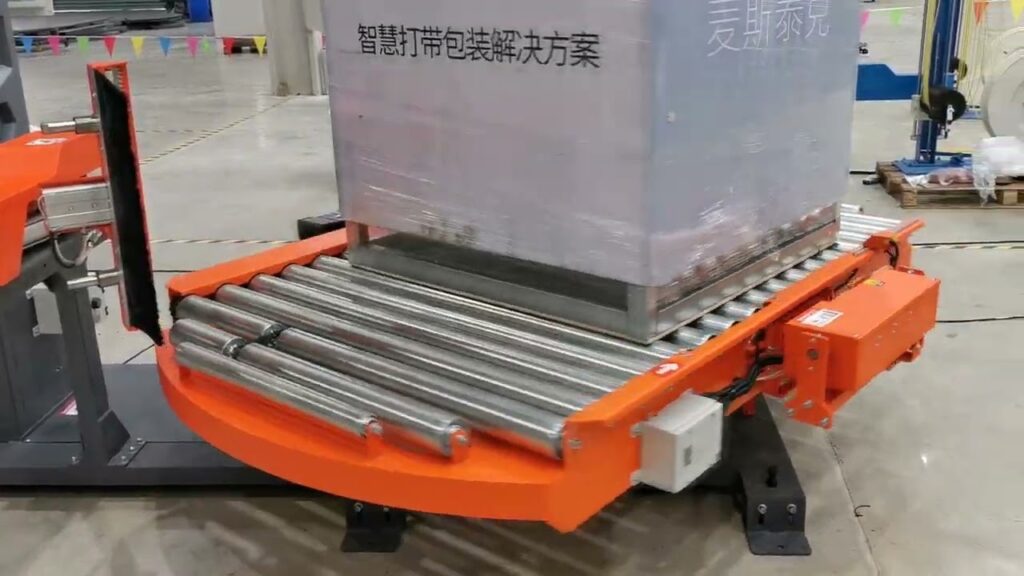

If you require a reliable and fully automatic pallet wrapping machine that is fast and efficient, then look no further than the SMART WASP Model S300. This pallet wrapping machine guarantees excellent results and is designed to handle a wide variety of load sizes with ease.

Overview:

The SMART WASP Model S300 is a fully automatic online pallet wrapping machine that has become a popular choice for many businesses due to its efficiency and reliability. It is designed to wrap, protect, and stabilize pallet loads quickly and safely. The machine is ideal for a range of industries, including beverage, food, pharmaceutical, and logistics.

This pallet wrapping machine features a user-friendly interface and a top-of-the-line control system that is intuitive to use. The machine also has a touch screen panel, which enables you to set the wrapping cycle parameters quickly and easily.

The S300 Pallet Wrapping Machine is equipped with a pre-stretch unit, capable of stretching the film by up to 300%, which helps you save on wrapping material costs and enhance the wrapping quality.

Operation:

The SMART WASP Model S300 is designed to be highly efficient and user-friendly for any operator. It is fully automated, which means that it operates without the need for constant supervision. This functionality significantly minimizes the risk of human error.

One of the significant advantages of this pallet wrapping machine is that it can cut and seal the film automatically, which saves significant time and effort.

The machine is equipped with an automatic film-wrapping function, which is programmable to multiple wrapping cycles. The intelligent control system integrates the pallet-lifting, film-cutting, film-welding, and film-clamping functions to provide complete automation.

Maintenance:

The SMART WASP Model S300 is a durable machine built to last. However, like any equipment, it is essential to maintain it to ensure optimum performance, extend its lifespan, and prevent breakdowns.

Regular maintenance includes checking the machine’s mechanical components such as gears, belts, motors, and moving parts, cleaning and lubricating the machine’s core and exterior, and checking for wear and tear on the key components.

Choosing the Right Supplier:

When selecting a supplier for the SMART WASP Model S300, you need to ensure that they are reputable and experienced. A reputable supplier will not only offer excellent product quality and service but also have extensive industry knowledge and experience in the field.

FAQs:

Q: How long does it take to wrap a pallet?

A: The SMART WASP Model S300 is designed to wrap pallets quickly, and it takes an average of 60 seconds to wrap a pallet.

Q: Can the machine operate without supervision?

A: Yes, the SMART WASP Model S300 is fully automated and can operate without constant supervision.

Q: What is the maximum load that the machine can handle?

A: The SMART WASP Model S300 can handle up to 3000KG loads, making it versatile enough to handle a wide variety of load sizes.

Summary:

The SMART WASP Model S300 Pallet Wrapping Machine is a reliable and fully automated machine designed to wrap, protect, and stabilize pallet loads quickly and safely. It is equipped with a pre-stretch unit that stretches the film by up to 300%, which helps you save on wrapping material costs. This pallet wrapping machine is ideal for several industries, including beverage, food, pharmaceutical, and logistics. It is user-friendly, easy to operate, and requires minimal supervision. If you want to enhance the productivity and efficiency of your business operations, you should consider the SMART WASP Model S300 Pallet Wrapping Machine.